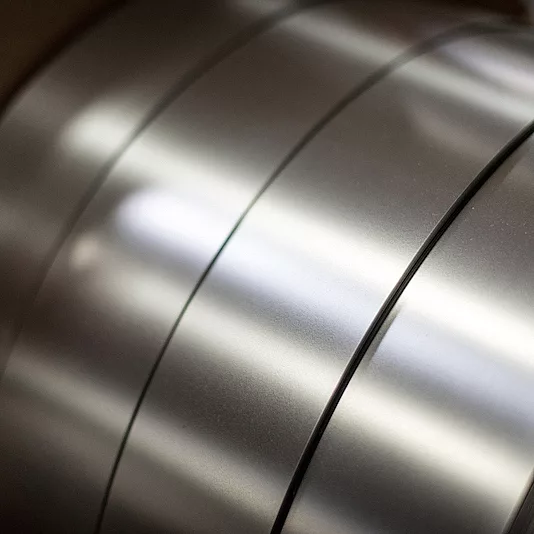

Stainless steel strip is a steel product used in applications that require durable and corrosion-resistant material.

Stainless Steel Strip is a steel product manufactured from the hot rolled strip and then pickled. This SS Strip is made up of austenitic stainless steel consists of chromium, nickel, and manganese as the main constituents, which offers excellent thermodynamic properties such as specific heat capacity, melting point, thermal conductivity and coeficient of linear expansion.

Strip steel, or coil steel, is usually known as carbon or stainless steel. Carbon steel strip is mainly iron and carbon. It also has small amounts of other things like manganese, phosphorus, sulfur, and silicon. Stainless steel strip has iron, carbon, and chromium. It can also have extra things like nickel, molybdenum, and different alloys. These extras help it resist rust and make it stronger. The exact mix and traits of strip steel can change. It depends on what it’s going to be used for.

One of the biggest pluses of stainless steel is that it’s really tough. It doesn’t get damaged easily, even when lots of people walk over it every day, or when it rains, snows, or gets really sunny. Stainless steel doesn’t rust or start to look old and worn out quickly. This means that once you install these strips, they will keep looking good and working well for a long time, helping everyone move around safely.

Safety comes first, and stainless steel tactile strip are designed with this in mind. They have special textures on them that stop people from slipping, making it safer to walk, especially in wet or crowded places. Plus, they can be a bit shiny, so when light hits them, they reflect it back. This makes it easier for everyone to see them, adding an extra layer of safety.

Nobody likes spending a lot of time or money on upkeep, and that’s where stainless steel strips shine. They are super easy to take care of. You don’t need to do much to keep them looking great. Just a simple cleaning once in a while is enough. Because they are so durable and low-maintenance, they save money over time. You won’t need to replace them as often as other types, making them a smart choice for anyone looking to order tactile strip for the blind or searching for affordable tactile warning surfaces.

Sunny Steel stainless steel strip product is manufactured and rolled to the tightest tolerances, allowing it to be used in applications where precision, strength, and durability are unparalleled.

We ensure that our high-quality coils are always available, no matter the location or time. Whether you need stainless steel, carbon steel, or specialty alloy coils, we keep a comprehensive inventory to meet your requirements promptly. With our extensive distribution network, you can rely on quick delivery and consistent supply, ensuring your projects stay on track without delay.

Stainless steel strip is rolled to precision gauges down to .0008″ with exacting specifications in widths from 024″ up to 40″ wide.

All grades available in stainless steel strip are listed below.

Our 301 stainless steel is available in precision rerolled steel strip in a variety of thicknesses. 301 stainless is a versatile austenitic grade, it is commonly used for applications such as precision spring manufacturing, stampings, fasteners, computer parts, etc.

Our 302 and 304 stainless steel strip grades are ideal for applications requiring corrosion resistance and high temperatures.

304 DDQ steel strip contains a higher nickel content than 304, allowing for more difficult deep drawing processes when needed.

Often used for deep drawn and spun components, our 305 DDQ stainless steel strip features corrosion resistance similar to 304/L with less work hardening due to increased nickel content. 305 DDQ stainless is commonly used in the eyelet industry and other similar applications that require a low rate of work hardening. These applications are typically subjected to severe cold forming during fabrication.

Of the austenitic grades, 316 and 316L DDQ steel strip is one of the most commonly used grades for deep draw metal stampings, with the higher nickel DDQ version used for the most severe deep draws where strength and corrosion resistance are important.

Our 317 stainless steel strip is ideal for applications requiring corrosion resistance and exposure to sulfuric acid compounds. Common uses of 317 stainless includes products such as heat exchangers, boilers and super heater elements because of the high operating temperatures.

Our 321 stainless steel is a titanium stabilized austenitic grade that is suitable for high temp applications. In addition to our large inventory of sheet, plate, bar, and hex, we are a supplier of 321 stainless steel strip in custom thicknesses.

Like our other 300 series austenitic grades, our 347 stainless steel strip is non-magnetic. SS 347 steel strip is stabilized against chromium carbide formation through the addition of columbium and tantalum, and is available in multiple thicknesses. Common applications of 347 stainless include high temperature gaskets, aircraft components, chemical production equipment, and others.

| ASTM | JIS | AISI | EN | Mill's Standard | |

|---|---|---|---|---|---|

| Grade | S30100 S30400 S30403 S31008 S31603 S32100 S41008 S43000 S43932 S44400 S44500 |

SUS301 SUS304 - SUS310S - SUS321 SUS410S SUS430 - SUS444 SUS430J1L |

301 304 304L 310S 316L 321 410S 430 - 444 - |

1.4310 1.4301 1.4307 1.4845 1.4404 1.4541 - 1.4016 1.4510 1.4521 - |

201 202 204Cu3 |

Stainless steel tape is a kind of metal material widely used in various industrial fields, known for its excellent corrosion resistance, high temperature properties and mechanical strength. So how is this key material made?

The manufacturing of stainless steel belts begins with the selection of appropriate raw materials. Usually, the main components of stainless steel are iron, chromium and nickel, of which chromium content is at least 10.5%, which makes stainless steel has excellent corrosion resistance. In addition to these main components, other elements may be added to improve their properties, such as carbon, manganese, silicon, molybdenum, copper, etc.

In the melting stage, the mixed raw material is put into an electric arc furnace or induction furnace for melting. The temperature inside the furnace usually reaches about 1600 degrees Celsius. The molten liquid steel is refined to remove impurities and gases from it.

The liquid stainless steel is poured into the continuous casting machine, and the stainless steel strip is formed through the continuous casting process. In this process, liquid stainless steel is continuously cast into a rotating mold to form a strip blank of a certain thickness. The cooling rate and temperature control of the mold have an important effect on the quality and performance of the strip.

The billet is hot rolled by a hot rolling mill to form a steel plate with a certain thickness and width. During the hot rolling process, the steel plate is subjected to multiple rolling and temperature adjustments to obtain the desired size and properties.

In this process, the stainless steel strip is soaked in an acidic solution to remove surface oxides and impurities. The surface of the stainless steel strip after pickling is smoother, which provides a good foundation for subsequent cold rolling and surface treatment.

At this stage, the stainless steel strip is further rolled through a cold mill to further adjust its thickness and flatness. The cold rolling process can improve the surface quality and precision of the stainless steel strip.

After a series of post-treatment processes such as annealing, polishing and cutting, the stainless steel strip finally completes the manufacturing process. The annealing process can eliminate the stress inside the stainless steel strip, improve its plasticity and toughness; Polishing process can make the surface of the stainless steel strip more smooth and bright; The cutting process cuts the stainless steel strip to the desired length and width as needed.

Stainless Steel Strips are widely used in various industries including chemical & food processing industries, construction & building materials, automobile industries, air conditioning & refrigeration, and washers industries. From this, I’ll explain a few applications in detailed.

Cold Rolled Stainless Steel Strips is one of a popular product in automobile industries that is used for body panels and the other automotive components. Using stamping methods the cold-rolled stainless steel strips can be formed into required shape panels or other required components.

Stainless Steel products are most broadly used and can be easily recycled. There are different manufacturing technologies for producing high-quality stainless steel strips that offer great advantages to building and construction industries. Stainless Steel Strips are used to make the structure of building or constructions and also used stainless steel strips for doors.

As the stainless steel strips have excellent thermodynamic properties like thermal conductivity, heat capacity, and melting points, as we discussed earlier. This stainless steel strip is used between the side by side refrigerators. Many times SS Strips can be used to manufacture condensers in refrigerators and air conditioners.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications.

We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.