Stainless steel sheet offers exceptional corrosion resistance, strength, and versatility for construction, automotive, aerospace, and food processing industries.

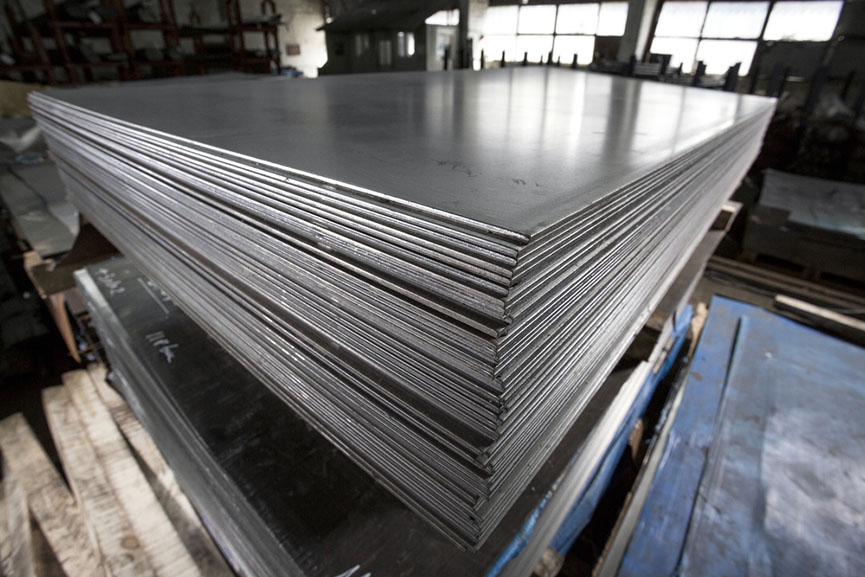

They are manufactured through hot or cold rolling, compressing stainless steel into thin sheets with a consistent thickness. They are composed primarily of iron, along with a minimum of 10.5% chromium, which forms a protective oxide layer on the surface, known as the passive layer.

Stainless steel sheet is a versatile material renowned for its outstanding properties, making it a staple in various industries, including construction, automotive, and manufacturing.

One of the most notable attributes of stainless steel sheet is its exceptional resistance to corrosion and rust. This is primarily due to the presence of chromium, which forms a passive layer of chromium oxide on the surface. This layer protects against oxidation and prevents the material from deteriorating in harsh environments.

Stainless steel sheets are known for their robust strength. Their high tensile strength ensures they can withstand significant stresses and strains without deforming, making them ideal for structural and load-bearing applications. The durability of stainless steel sheet metal makes it a cost-effective choice, as it often has a longer lifespan than other materials.

Stainless steel sheets can maintain their mechanical properties and structural integrity at both high and low temperatures. This resistance to oxidation and scaling at elevated temperatures makes them suitable for use in environments with extreme heat, such as industrial furnaces and heat exchangers.

Besides its functional characteristics, stainless steel sheet metal is also valued for its aesthetic qualities. It has a clean, modern appearance that can be further enhanced by various finishes, such as brushed, mirrored, or matte. This aspect makes stainless steel sheets an attractive option for architectural and decorative applications.

The non-porous surface of stainless steel sheet metal is easy to clean and sanitize, making it a preferred choice in industries where hygiene is paramount, such as food processing, pharmaceuticals, and medical equipment. The material does not support bacterial growth, contributing to a safer and more sanitary environment.

Stainless steel sheets are available in a wide range of grades and thicknesses. Whether you need a thin, flexible sheet for a lightweight application or a thicker, more rigid sheet for heavy-duty use, stainless steel suppliers like Metal Supermarkets can provide the right type to meet specific project requirements.

Despite their strength, stainless steel sheets are relatively easy to fabricate. They can be stamped, welded, cut, and formed into various shapes without losing their intrinsic properties. This workability allows for great design flexibility, making stainless steel sheet metal a favourite among engineers and designers.

Stainless steel sheet metal comes in various grades, offering specific properties and characteristics. The most common grades include austenitic stainless steel (such as 304 and 316), ferritic stainless steel, and martensitic stainless steel.

Stainless Steel 304 Sheet is an austenitic stainless steel that contains 18% chromium and 8% nickel.

304 Stainless Steel Sheet, is the most popular and economical of the stainless steels. 304 Stainless Sheet offers good corrosion resistance to many chemical corrodents as well as industrial atmospheres and marine environments. 304 Stainless Sheet may become slightly magnetic when worked and is not heat treatable. Grain direction on polished sheets is random and not guaranteed unless specified or custom quoted.

316/316L stainless steel sheet is a popular grade of stainless steel where superior corrosion resistance is paramount.

316 stainless sheet is widely used in marine and highly acidic environments, underwater equipment, surgical tools, food and pharmaceutical applications.

The addition of molybdenum increases the corrosion resistance of 316 stainless over the more economical 304 grade.

Stainless steel sheets are used in many industries and applications, including:

Stainless steel sheet metal is a versatile material used extensively in architectural and construction projects. They are employed for decorative purposes, cladding, roofing, wall panels, elevator interiors, and handrails. Stainless steel sheets offer durability, corrosion resistance, and an attractive appearance, making them ideal for interior and exterior applications.

Stainless steel metal is widely utilized in the food industry, including commercial kitchens, food processing plants, and restaurants. Thanks to its hygienic properties, easy-to-clean surfaces, and resistance to stains and corrosion, stainless steel sheet can be used for food preparation surfaces, countertops, backsplashes, sinks, and equipment.

Stainless steel sheets are used for various automotive components, including exhaust systems, trim, grills, decorative accents, and structural parts. Stainless steel sheets provide corrosion resistance, heat resistance, and a sleek appearance, contributing to both functionality and aesthetics.

Stainless steel sheets are used for surgical instruments, medical equipment, hospital fixtures, dental tools, and implants. Stainless steel’s biocompatibility, sterilization capabilities, and resistance to corrosion and staining make it suitable for critical healthcare environments.

Stainless steel sheets are used for tanks, pressure vessels, storage containers, process piping, machinery components, and equipment. Stainless steel sheets offer high strength, corrosion resistance, and heat resistance, making them ideal for demanding industrial applications.

Due to its resistance to corrosion and environmental factors, stainless steel sheet metal finds applications in renewable energy system components, including solar panels, wind turbines, and hydroelectric power plants.

Stainless steel sheets are popular in artistic and decorative projects. They are used for sculptures, wall art, signage, furniture, and interior design elements. Stainless steel’s aesthetic appeal, flexibility, and ease of customization make it a preferred choice for creative applications.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications.

We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.