17-7 PH

Read more

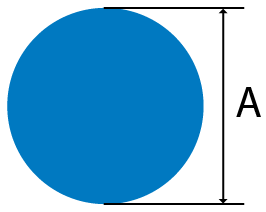

Explore our extensive stainless steel round bar stock with over 15 grades and a variety of sizes. We offer unmatched supply capabilities, including in-house processing to improve your supply chain. Quality and reliability for your engineering raw material needs.

Stainless Steel Round Bars are cylindrical steel bars known for their durability, corrosion resistance, and strength, making them ideal for various industrial applications. They are made from a strong, corrosion-resistant alloy comprising nickel, chromium, and molybdenum. These bars offer great resistance against wear and tear and have excellent heat transfer characteristics due to their low thermal expansion coefficient. They can also be blended with other metals, such as steel or aluminum, for enhanced strength and durability.

Stainless steel round bars are made from a variety of materials, including austenitic, martensitic, and ferritic stainless steel.

Austenitic stainless steels are the most common and are known for their high strength, durability, and corrosion resistance.

Martensitic stainless steels are known for their hardness and are often used in applications that require a high level of wear resistance.

Ferritic stainless steels are less commonly used but are known for their corrosion resistance and high-temperature performance.

They are also highly resistant to heat and chemicals, making them ideal for use in a variety of harsh environments.

Additionally, stainless steel round bars can be easily machined and welded, making them a versatile choice for a wide range of applications.

In addition to their mechanical properties, stainless steel round bars are also highly attractive and can be finished in a variety of ways to create a polished, professional look.

They are also highly recyclable, making them an environmentally friendly choice for companies looking to reduce their carbon footprint.

Stainless steel round bars are an essential component in a variety of industries, from construction to manufacturing to transportation.

By using high-quality materials and advanced manufacturing techniques, stainless steel round bar manufacturers can create bars that offer superior strength, durability, and corrosion resistance.

Whether you're looking for a strong, durable material for your next project or simply want to take advantage of the many benefits of stainless steel, stainless steel round bars are a versatile and reliable choice.

Stainless Steel Round Bars are produced through a process of extrusion or rolling and come in various sizes and grades, with 304 and 316 being the most common types.

Stainless Steel Round Bar 304/304L is a round shaped 304/304L Stainless Steel Alloy bar.

304/304L Stainless Steel Alloy has excellent mechanical properties and is resistant to many corrosive agents.

316 Stainless Round is widely used in applications exposed to chemical corrosives as well as marine astomosperes. 316L Stainless Round Bar has a very low carbon content which minimises carbide precipitation due to welding. 316L Stainless is widely used in marine applications, paper processing equipment and many other applications where moisture will be present.

316 Stainless Round Bar is stocked in sizes ¼'' to 6'' round, if you require a size that is not listed please contact us to enquire. This product is dual certified 316/316L.

17-7 PH is a precipitation-hardened stainless steel that is well suited for aerospace and other applications requiring high strength and good corrosion resistance and formability.

17-4PH is a precipitation hardened(PH) martensitic stainless steel consisted of copper and niobium/tantalum.

The manufacture of stainless steel round bars involves several steps:

Supporting industries such as construction, oil and gas, automotive, and defense, stainless steel plays a vital role in various commercial engineering applications. Known for its excellent corrosion resistance, good machinability, and workability, stainless steel offers superior temperature resistance, exceptional durability, and aesthetic appeal. Moreover, this versatile alloy is 100% recyclable, making it an environmentally friendly choice for modern industries.

In the construction industry, stainless steel bars are commonly used for reinforcing concrete structures, providing roofing support, and framing structures for buildings and bridges. The round bars are also used as dowel bars to join concrete and support pavements, highways, and bridges.

Industries such as automotive, aerospace, and marine rely heavily on stainless steel round bars for their strength, durability, and ability to perform in harsh environmental conditions. The round bars are used in the manufacture of engines, transmissions, exhaust systems, and more components.

The food and beverage industry also uses stainless steel rods to maintain a clean and hygienic environment. The round bars are used to manufacture equipment such as mixing tanks, storage tanks, and piping systems. Stainless steel’s resistance to corrosion also makes it ideal for processing acidic foods and beverages.

Stainless steel round bars are commonly used in the medical industry for their ability to withstand sterilization, corrosion resistance, and strength. The round bars are used for manufacturing surgical instruments such as forceps, scissors, and tweezers. Stainless steel is also used for implants such as bone screws and dental implants due to its ability to integrate with the body.

The energy industry also relies heavily on stainless steel round bars for their resistance to corrosion and ability to withstand extreme temperatures. The round bars are used in the manufacture of heat exchangers, boilers, and condensers.

Stainless steel round bars offer a range of aesthetic benefits thanks to their sleek and professional look. They are extremely durable, can last for years without requiring any maintenance or repair, and are heat-resistant and non-corroding. Their uniform shape allows them to be used in many applications, such as handrails, railings, fences, outdoor furniture, gazebos, and even more modern applications like sculptures with intricate patterns. The attractive mirror finish adds an appealing finesse that will enhance the overall look of any space while remaining low maintenance due to its corrosion resistance. Stainless steel is also hygienic, which makes it perfect for environments where hygiene is important such as hospitals or restaurants.

Stainless steel round bars are highly sustainable due to their superior corrosion, wear, and fatigue resistance. They are non-toxic, 100% recyclable with no loss of properties post-recycling process. They are highly durable (up to 20 times more resistant than carbon steels depending on the alloy) and economical (with fewer maintenance costs). Moreover, stainless steel has a longer lifespan than other building materials and is easy to clean and maintain. This means it can be used for applications in traditional and modern construction projects with minimal environmental impact over its long lifetime.

Stainless steel round bars offer a range of benefits that make them an excellent choice for various applications in different industries. Their durability, corrosion resistance, strength, aesthetics, and sustainability contribute to their popularity and widespread use. Stainless steel round bars are worth considering if you are looking for a durable, low-maintenance, and reliable material. Whether you are involved in construction, manufacturing, or transportation, using stainless steel round bars can help you save time and money in the long run.

Stainless steel is renowned for its superior corrosion-resistant characteristics, making it highly resistant to staining and ideal for hygienic environments. This versatile alloy is widely used in the oil, gas, and petrochemical industries due to its durability and resistance to harsh conditions. Stainless steel is relatively easy to process and machine, offering impressive workability that enhances its appeal in various applications. Its combination of strength, corrosion resistance, and hygienic properties makes stainless steel a popular choice for industries requiring robust and reliable materials.

Our stainless steel round bar stock is extensive, offering over 15 distinct grades and a vast selection of incremental sizes. The sheer scale of our inventory, combined with in-house processing capabilities, ensures that we provide an unrivaled supply proposition within the stockholding sector. Whether you're sourcing raw materials for engineering purposes or looking to improve your supply chain efficiency, we have the expertise and resources to meet your needs.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications.

We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.