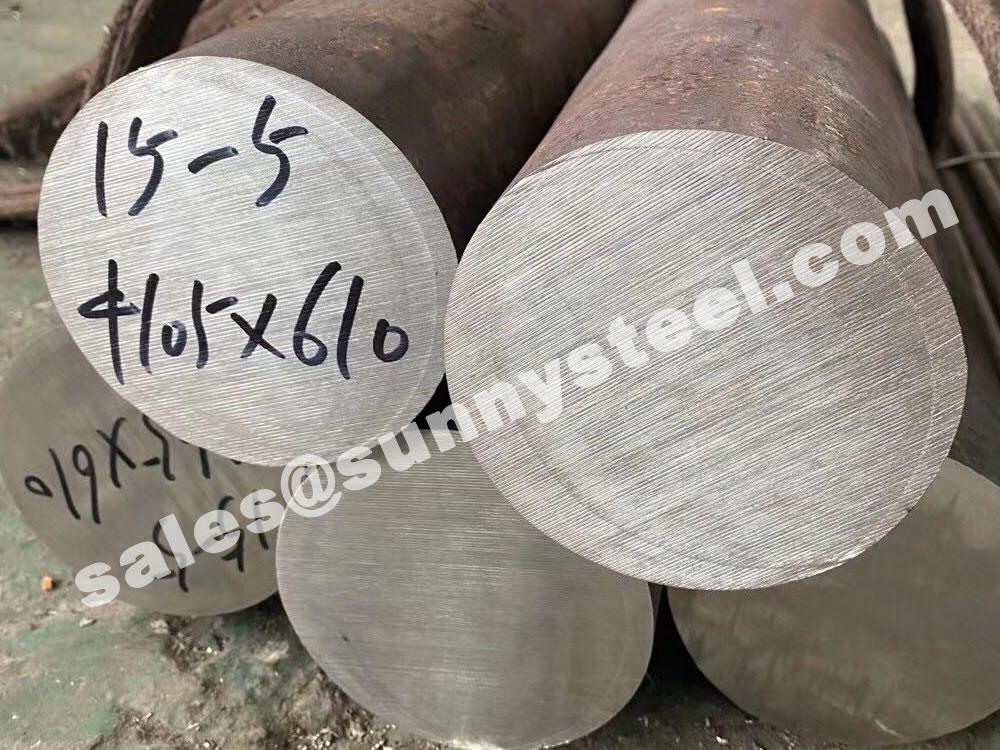

15-5 Stainless is a precipitation hardening material, similar to 17-4.

Its name reflects the 15% chromium and 5% nickel chemical composition of the alloy. 15-5 is renowned for its corrosion resistance and ability to withstand harsh atmospheric conditions. It was developed to offer enhanced mechanical properties and greater toughness than the more prevalent 17-4 stainless.

15-5 Stainless is a modification of 17-4 PH Stainless. Both display physical properties of great tensile strength and mild corrosive resistance. These properties are preserved at temperatures at up to 600°F. 15-5 stainless is formed with better toughness than 17-4.

15-5 primarily comes in the annealed state and can be heat treated/aged at lower temperatures to enhance the mechanical properties and durability even further.

| Condition | Tensile | Yield | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| Annealed | 160 | 140 | 8 | – | C35 |

| H1075 | 160 | 160 | 12 | – | C38 |

| H900 | 210 | 200 | 9 | – | C46 |

| Carbon | Chromium | Columbian + Tantalum | Copper | Manganese | Nickel | Phosphorus | Silicon | Sulfur |

|---|---|---|---|---|---|---|---|---|

| 0.070 Max | 14.0 - 15.50 | 0.15 - 0.45 | 2.50 - 4.50 | 1.00 Max | 3.50 - 5.50 | 0.040 Max | 1.00 Max | 0.30 Max |

15-5 is typically provided in Condition A and can undergo heat treatment at various temperatures and for different durations to attain a broad spectrum of properties. The following is a sample of standard heat treatments for the 15-5 material in Condition A:

| Condition | Heat to ( +/- 15F / 8.4 ℃ ) | Time at temperature ( H ) |

|---|---|---|

| H900 | 900 F / 482 ℃ | 1 |

| H1025 | 1025 F / 551 ℃ | 4 |

| H1075 | 1075 F / 580 ℃ | 4 |

15-5 stainless steel is commonly used in the aerospace, chemical, marine, and petrochemical industries. Typical applications include structural components, fasteners, fittings, and valves. Its high strength and corrosion resistance make it ideal for parts exposed to stress and corrosive environments.

There are numerous varieties of stainless steel that could be employed in the fabrication of a bespoke wire basket or tray. Each distinct formulation of stainless steel alloy possesses distinctive characteristics, including tensile strength, melting point, oxidation resistance, and corrosion resistance.

Picking the right grade of stainless steel requires knowing what your options are. To help you better understand your choices, here’s a quick explanation of the most common types of stainless steel and their properties:

While there are thousands of different alloys of stainless steel, they can all be divided into three broad categories:

These are the most frequently used types of stainless steels. Austenitic stainless steels tend to have a high chromium content compared to other steel alloys, giving them a higher resistance to corrosion. Another common characteristic of austenitic stainless steel alloys is that they tend to be non-magnetic—though they may become magnetic after cold working.

The second most common form of stainless steel after austenitic alloys. As the name implies, ferritic stainless steel is magnetic. These alloys can be hardened through cold working. They also tend to be less expensive because of their reduced nickel content.

The least common category of stainless steel alloy. Their corrosion resistance tends to be lower than either ferritic or austenitic alloys, but they have a high hardness. Martensitic stainless steel alloys are often ideal for applications requiring extraordinarily high tensile strength and impact resistance. When said applications also require corrosion resistance, these alloys may be used with a protective polymer coating.

This category of stainless steel derives its name “duplex” from its composition; it is made of half austenite and half delta-ferrite. These stainless steel alloys have better corrosion resistance, especially against chloride pitting, and higher tensile strength than standard austenitic stainless steels. Due to their physical properties and chemical resistance, duplex stainless steels are used widely in the oil and gas industry for pipework systems or as pipelines and pressure vessels in the petrochemicals industry.

This category of stainless steel is comprised of durable, corrosion-resistant alloys with exceptional strength. They can be treated to yield strengths three to four times that of standard austenitic stainless steel. They are most commonly used in the aerospace, nuclear, and oil and gas industries.

There are numerous grades of stainless steel within each category—here are the breakdowns of the most common varieties of each:

Grade 301 stainless steel, enriched with chromium and nickel, boasts exceptional corrosion resistance. It exhibits both strength and ductility when subjected to cold working processes. These attributes make Grade 301 a popular choice for welding, forming, and drawing applications.

Grade 302 stainless steel, with a composition akin to Grade 304 but with a higher carbon content, is renowned for its resilience against corrosive solvents, chemicals, and acids. It is widely utilized in the fabrication of conical compression springs and is a common feature in kitchen machinery and food processing equipment.

Grade 303 is a non-magnetic austenitic stainless steel, renowned for its superior machinability. It does not harden through heat treatment and, while not as corrosion-resistant as Grade 304, it is still a formidable contender. This grade is frequently employed in the production of intricately machined components such as gears, aircraft fittings, and fasteners like screws, shafts, nuts, and bolts.

As the quintessential stainless steel, Grade 304 is celebrated for its versatility and is a staple in Marlin Steel's custom wire basket designs. It is distinguished by its impressive tensile strength, approximately 621 MPa (90 ksi), and can operate at a high maximum temperature of around 870˚C. The synergy of tensile strength, temperature resistance, and corrosion resistance positions Grade 304 as an ideal material for a diverse range of applications.

This nickel-chromium alloy shares the machinability traits of Grade 304, coupled with high tensile strength and chemical resistance. Grade 309's ability to endure extreme temperatures makes it well-suited for high-heat applications, including oven linings, aircraft engines, automotive exhaust components, and furnace parts.

A prevalent austenitic stainless steel, Grade 316 possesses a tensile strength of 579 MPa (84 ksi) and can be used up to a maximum temperature of approximately 800˚C (1,472˚F). While it may have a slightly lower tensile strength and temperature tolerance than Grade 304, Grade 316 offers superior resistance to chlorides, such as salt, making it a preferred material for applications exposed to saltwater or other chlorides.

Similar to other austenitic stainless steels, Grade 317 is characterized by its high tensile strength, corrosion resistance, and rich nickel and chromium content. The addition of molybdenum in Grade 317 enhances its resistance to chloride-induced pitting, making it an excellent choice for chemical processing and marine applications, despite its higher cost compared to similar stainless steels.

Grade 321 stainless steel, with the inclusion of titanium, is designed to withstand chemical and high-temperature corrosion. It resists oxidation up to 1500 degrees Fahrenheit and exhibits superior stress rupture properties compared to Grade 304. It remains non-magnetic and maintains its strength even at cryogenic temperatures.

Enriched with columbium and tantalum, Grade 347 stainless steel maintains its durability at high temperatures. This non-magnetic grade is ideal for welding and applications involving intermittent heating between 800 and 1650 degrees Fahrenheit. It is also quite ductile, allowing for stamping, spinning, and drawing as required.

Stainless steel is different from other types of steel in that it contains nickel, chromium and other alloying elements. This key difference provides it with a much improved degree of corrosion resistance.

Grade 405 stainless steel, with its lower corrosion resistance compared to Grade 430, is well-suited for mildly corrosive environments. Its unique aluminum content prevents hardening upon cooling after welding, making it ideal for applications such as steam nozzles and quenching racks.

This grade boasts high heat resistance, albeit with subpar corrosion resistance. It is formulated with an 11% chromium and 8% nickel composition.

Grade 409 exhibits both high-temperature tolerance and corrosion resistance. It is particularly resistant to exhaust gases and atmospheric corrosion, although not as much as Grade 430. Consequently, Grade 409 stainless steel is often utilized in automotive exhaust systems.

This grade leads in hardness among stainless steels with 12% chromium, reaching 50HRC. Grade 420 also provides good ductility and corrosion resistance, especially against alkalis, fresh water, food, and mild acids. It is commonly used in cutlery due to its corrosion resistance, although pitting can occur with prolonged exposure to certain foods.

While not as strong as the austenitic alloys mentioned, Grade 430 stainless steel offers exceptional resistance to nitric acid. With a tensile strength of 450 MPa (65 ksi), it is more than adequate for many heavy-duty applications despite being lower than most austenitic stainless steels.

A stronger alternative to Grade 430, Grade 434 stainless steel has a tensile strength of 540 MPa (78 ksi) and can operate at a maximum temperature of 815˚C (1,499˚F). This makes it slightly superior to 316 stainless for high-temperature applications and tougher than Grade 430. Grade 434 also excels in pitting resistance compared to Grade 430 stainless steel.

A variant of Grade 434, Grade 436 incorporates columbium and molybdenum to minimize roping or ridging during stretch forming. Highly magnetic and fairly abrasion-resistant, Grade 436 is commonly used in appliance trims and automotive applications.

As one of the most popular precipitation hardening grades of stainless steel, Grade 442 is utilized across various industries. Ductile and relatively soft for a steel alloy, it withstands high friction, offering high strength and good corrosion resistance.

Grade 444 is a low-carbon stainless steel enhanced with molybdenum for excellent pitting and oxidation resistance. It boasts properties from high strength to good ductility, allowing for a broad range of stretch bending operations. However, it has limited weldability. Grade 444 is well-suited for applications such as roofing and coating in marine environments and food processing equipment.

Martensitic stainless steel is a type of stainless steel alloy that has a martensite crystal structure. It can be hardened and tempered through aging and heat treatment. The other main types of stainless steel are austenitic, ferritic, duplex, and precipitation hardened.

Grade 410 is a versatile martensitic stainless steel known for its corrosion resistance, which can be augmented through hardening, polishing, and tempering processes. While not as corrosion-resistant as austenitic stainless steels, Grade 410 performs admirably in mildly corrosive environments.

This low carbon variant of Grade 410 stainless steel retains its non-hardening characteristic even at elevated temperatures, maintaining ductility and softness amidst rapid temperature fluctuations. Grade 410S's resistance to cracking during welding and high-heat exposure makes it a staple in thermal processing, petroleum refining, and other petrochemical industry applications.

Grade 414 stainless steel is essentially Grade 410 with the added benefit of nickel. The enhanced nickel content fortifies Grade 414, making it stronger than Grade 410 at comparable thicknesses. This grade is widely utilized in the fabrication of mining equipment, including forged shafts, spindles, beater bars, fasteners, and valve seats.

Boasting a machinability rating of 85%, Grade 416 stainless steel stands as the most machinable of all stainless steels. Its cost-effectiveness and superior machinability make it available in various conditions, such as highly tempered, hardened, or unhardened. Though less corrosion-resistant than austenitic steels, Grade 416 is highly resistant to fresh water, acids, and alkalis, making it ideal for automatic screw-machined components, gears, bolts, and washing machine parts.

When annealed, Grade 420 stainless steel possesses a tensile strength of approximately 586 MPa (85 ksi). Upon hardening and stress relieving, this grade's tensile strength soars to around 1,586 MPa (230 ksi). While not as chemically resistant as other austenitic and ferritic stainless steels, Grade 420 demonstrates good resistance to mild acids, water, some alkalis, and food compounds, which is why it's frequently used in cutlery production. Grade 420 stainless steel is a top contender when tensile strength and impact resistance are paramount.

The high carbon content in Grade 440 stainless steel enables it to be heat-treated, offering exceptional wear resistance and edge retention. This grade is magnetic and exhibits moderate corrosion resistance. It is commonly employed in the manufacture of knives, scissors, and parts that are in contact with oil or gas.

Grade 2205 stainless steel, fortified with nitrogen, is crafted to withstand stress corrosion cracking, pitting, and crevice corrosion, offering nearly double the corrosion resistance of conventional austenitic steels. This grade is highly valued in the oil and gas, petrochemical, marine, and pulp and paper industries for applications demanding high strength and robust corrosion resistance.

While sharing the corrosion resistance of Grade 316 austenitic steel, Grade 2304 boasts nearly twice the yield strength of Grade 316 and other austenitic steels. It also performs capably in colder climates, with some reservations. This material is optimally suited for applications within the temperature range of -58°F to 572°F.

This duplex stainless steel is distinguished by its high thermal conductivity, formidable chloride stress corrosion resistance, and a low coefficient of thermal expansion. Grade 2507 is well-suited for applications that require superior corrosion resistance and substantial tensile strength. It is employed in marine and petrochemical equipment, offshore oil platforms, and a variety of mechanical and structural components.

This precipitation-hardening stainless steel is renowned for its exceptional strength and satisfactory corrosion resistance. The strength of Grade 17-4 can be adjusted through heat treatment processes. It also offers decent machinability and exhibits magnetic properties. Grade 17-4 is frequently utilized in the aerospace and petroleum, as well as chemical industries, for applications that require a balance of strength and resistance to corrosion.

Grade 15-5 is characterized by its high strength, corrosion resistance, transverse toughness, ductility, and hardness. While it is not suited for cold working, it performs well in hot working conditions. This precipitation-hardening (PH) stainless steel is often employed in high-pressure, corrosive environments and is particularly well-suited for the manufacture of aerospace components.

Here’s a stainless steel grade chart to break down the characteristics of the alloys listed above:

| Alloy | Tensile Strength | Maximum Use Temp | Melting Point | Resistance |

|---|---|---|---|---|

| Austenitic Alloys | ||||

| Grade 301 Stainless | 515 MPa (75 Ksi) | 871 °C (1600 °F) | 1399-1421°C (2550-2590°F) | Excellent corrosion resistance |

| Grade 302 Stainless | 585 MPa (85 Ksi) | 870˚C (1,679˚F) | 1400-1420 °C (2550-2590 °F) | Excellent corrosion resistance |

| Grade 303 Stainless Steel | 690 MPa ( 100 Ksi) | 760˚C (1,400˚F) | 1400-1420 °C (2550-2590 °F) | Lower corrosion resistance |

| Grade 304 Stainless | 621 MPa (90 Ksi) | 870˚C (1,679˚F) | 1,399 – 1,454˚C (2,550 – 2,650˚F) | Good overall resistance to corrosives |

| Grade 309 Stainless | 620 MPa (89 Ksi) | 1000˚C (1,832˚F) | 1400-1455 °C (2550-2651 °F) | Excellent corrosion resistance |

| Grade 316 Stainless | 579 MPa (84 ksi) | ~800˚C (1,472˚F) | 1,371 – 1,399˚C (2,500 – 2,550˚F) | Excellent chloride resistance |

| Grade 317 Stainless | 585 MPa ( 85 Ksi) | 816˚C (1,500˚F) | 1,370 – 1,400˚C (2,500 – 2,550˚F) | Good chloride resistance |

| Grade 321 Stainless | 620 MPa (90Ksi) | 816˚C (1,500˚F) | 1,400 – 1,425˚C (2,550 – 2,600˚F) | Excellent corrosion resistance |

| Grade 347 Stainless | 690 MPa (101 Ksi) | 816˚C (1,500˚F) | 1,400 – 1,425˚C (2,550 – 2,600˚F) | Excellent corrosion resistance |

| Ferritic Alloys | ||||

| Grade 405 Stainless | 585 MPa (85Ksi) | 815˚C (1,499˚F) | 1,480 – 1,530˚C (2,700 – 2,790˚F) | Good acid corrosion resistance |

| Grade 408 Stainless | 505 MPa (73 Ksi) | 815˚C (1,499˚F) | 1,400 – 1,455˚C (2,550 – 2,650˚F) | Resists well against most oxidizing acids and salt spray |

| Grade 409 Stainless | 448MPa (65 Ksi) | 815˚C (1,499˚F) | 1,425 – 1,510˚C (2,597 – 2,750 F) | Good corrosion resistance |

| Grade 420 Stainless | 760 - 1702 MPa (110 - 247 Ksi) | 427˚C (800˚F) | 1,455 – 1,510˚C (2,651 – 2,750 F) | Fairly corrosion resistant |

| Grade 430 Stainless | 450 MPa (65 ksi) | 815˚C (1,499˚F) | 1,425 – 1,510˚C (2,597 – 2750˚F) | Good nitric acid resistance |

| Grade 434 Stainless | 540 MPa (78 ksi) | 815˚C (1,499˚F) | 1,426 – 1,510˚C (2,600 – 2750˚F) | Superior pitting resistance |

| Grade 436 Stainless | 459 MPa (67 Ksi) | 815˚C (1,499˚F) | 1,425 – 1,510˚C (2,600 – 2,750˚F) | Excellent citric and nitric acid corrosion resistance |

| Grade 442 Stainless | 515-550 MPa (77 - 80Ksi) | 925-980˚C (1,700/1,800˚F) | 1,065 – 1,120˚C (1,950 – 1,120˚F) | Good corrosion resistance |

| Grade 444 Stainless | 415 MPa ( 60 Ksi) | 950˚C (1,752˚F) | 1,405 – 1,495˚C (2,561 – 2,723˚F) | Good oxidation resistance |

| Martensitic Alloy | ||||

| Grade 410 Stainless | 500 -1400 MPa (73 - 203 Ksi) | 650˚C (1,202˚F) | 1,482 – 1,532˚C (2,700 – 2,790˚F) | Good corrosion resistance to air, water, and some chemicals |

| Grade 410S Stainless | 444 MPa (64 Ksi) | 705˚C (1,300˚F) | 1,482 – 1,532˚C (2,700 – 2,790˚F) | Good oxidation resistance |

| Grade 416 Stainless | 517 MPa (75 Ksi) | 760˚C (1,400˚F) | 1,480 – 1,530˚C (2,696 – 2,786˚F) | Poor Chloride resistance. Good resistance to acids, alkalis & fresh water |

| Grade 420 Stainless | 586 MPa (85 ksi) when annealed 1,586 MPa (230 ksi) when hardened and stress relieved |

650˚C (1,202˚F) | 1,454 – 1,510˚C (2,649 – 2,750˚F) | Resistant to mild acids, alkalis, and water when hardened |

| Grade 440 Stainless | 758 MPa (110 Ksi) | 760˚C (1,400˚F) | 1,483˚C ( 2,700˚F) | Limited corrosion resistance |

| Duplex (Ferritic-Austenitic) Alloys | ||||

| Grade 2205 Stainless | 620 MPa (90 Ksi) | 300˚C (572˚F) | 1,385 – 1,443˚C (2,525 – 2,630˚F) | Excellent corrosion resistance |

| Grade 2304 Stainless | >600 MPa (>87 Ksi) | 570˚C (1058˚F) | 900 – 1,150˚C (1,650 – 2,100˚F) | Resistance to corrosion cracking |

| Grade 2507 Stainless | 800 MPa (116 Ksi) | 300˚C (572˚F) | 1,350˚C (2,460˚F) | Excellent chloride corrosion resistance |

| Precipitation Hardening (PH) Alloys | ||||

| Grade 17-4 Stainless | 1103 MPa (160 Ksi) | 316˚C (600˚F) | 1,404 - 1,440˚C (2,560 - 2,625˚F) | Excellent corrosion resistance |

| Grade 15-5 Stainless | 1380 MPa (200 Ksi) | 316˚C (600˚F) | 1,404 - 1,440˚C (2,560 - 2,625˚F) | Excellent corrosion resistance |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.