316 Stainless Steel Elbow

Designed for durability and corrosion resistance, making them ideal for various industrial applications.

Type 316/316L Stainless Steel is a molybdenum steel possessing improved resistance to pitting by solutions containing chlorides and other halides.

Type 316 is a molybdenum steel possessing improved resistance to pitting by solutions containing chlorides and other halides. In addition, it provides excellent tensile, creep and stress-rupture strengths at elevated temperatures. Type 316 is available in low carbon (316L) and high carbon (316H) alloys.

Alloy 316/316L is an austenitic alloy and similar to 304/304L is used in a wide range of applications. It is an important alloy when it comes to chloride environments and many other chemical process industries. The addition of Molybdenum significantly increases general corrosion resistance as compared to 304/304L and more importantly, increases the chloride pitting resistance.

316/316L has excellent forming and welding characteristics. Due to its superior chloride pitting resistance, it is commonly used in applications involving chlorides or halides. That property is also useful in marine environments.

It also has an excellent resistance to intergranular corrosion in as-welded condition. Dual grade becomes important if heavy gauge welding is performed. This is where intergranular corrosion comes into picture and having a lower carbon version makes it difficult for Chromium Carbide to precipitate in the 797 to 1580 degF (425 to 860 degC) range when the welding is going on for a long time due to the heavy gauge.

It has excellent creep and rupture strength at higher temperatures compared to 304/304L. Finally, it has excellent strength and toughness at cryogenic temperatures.

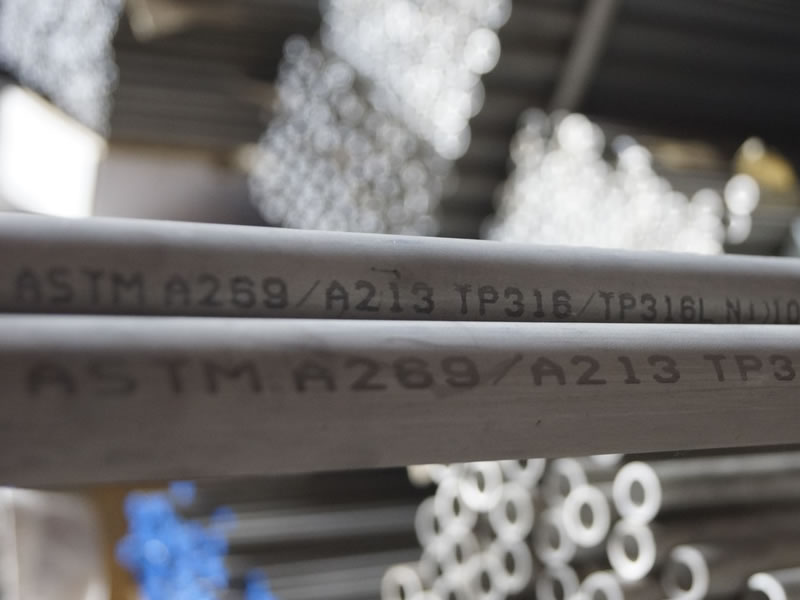

ASTM A269 TP316L stainless tube refers to a specific type of stainless steel tubing that conforms to the ASTM A269 standard and is made from grade TP316L stainless steel.

The ASTM A269 TP316 stainless tubes undergo a comprehensive quality assurance process, including underwater ultrasonic testing, eddy current testing, borescope inspection, spectroscopy, and roughness testing.

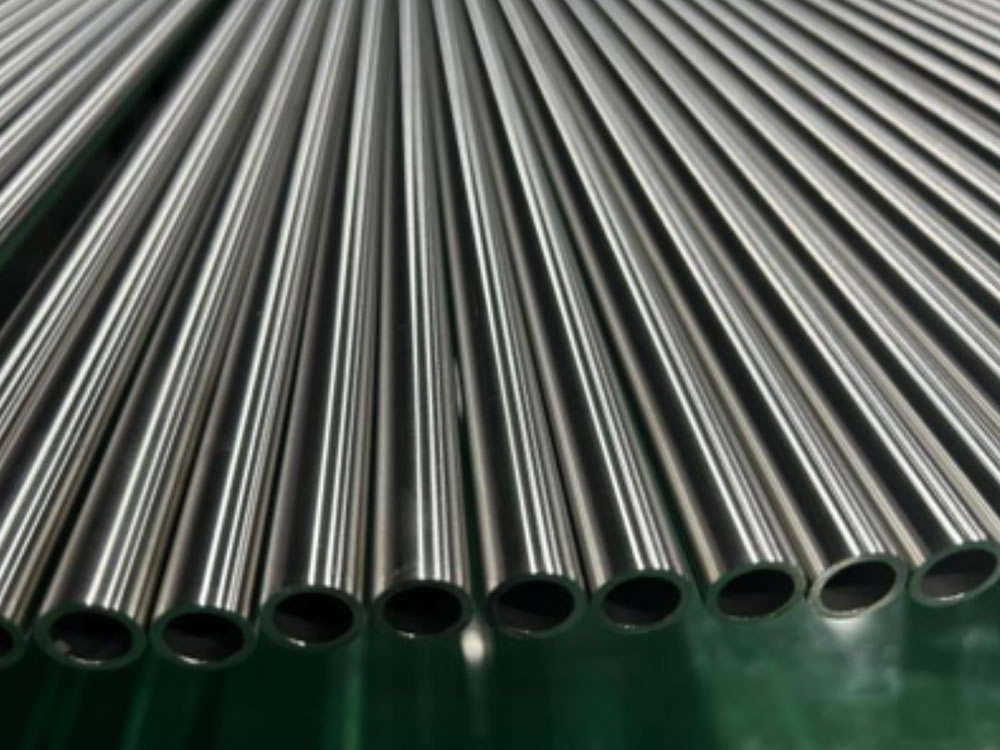

The terms AP, MP, BA, and EP refer to different surface finishes or treatments applied to the stainless steel.

These finishes are essential in various industries where the appearance, corrosion resistance, and cleanliness of the stainless steel are critical. Here's an explanation of each term:

EP stands for electropolished, a process where the stainless steel tube, after annealing and acid pickling, undergoes electropolishing using electrodes and acid in a tank, creating a chemical reaction to achieve a clean surface through electrochemical polishing. EP tubes are used in pipeline projects with high cleanliness requirements for the stainless steel tube surface.

AP refers to the condition where the surface of the stainless steel tube is treated after annealing through acid pickling to remove the oxide layer. Stainless steel industrial pipes sold in the market, known for their wide applications, are extensively used in the chemical industry for pipeline needs.

MP denotes a stainless steel seamless tube that undergoes mechanical polishing after annealing and acid pickling to achieve a bright and clean surface. This finish is primarily utilized in the pharmaceutical and food industries.

BA is specific to precision-rolled stainless steel tubes. Also known as precision tubes, BA tubes skip the regular annealing and acid pickling process after semi-finished rolling. Instead, they use argon gas in a vacuum annealing furnace to remove surface oil stains generated during the rolling process, preserving the brightness of the surface without leaving an oxide layer.

These surface finishes cater to various industry requirements, offering different levels of brightness, cleanliness, and corrosion resistance based on specific applications.

The versatility of ASTM A269 lends itself to a wide array of applications across various industries:

In aggressive chemical environments, where corrosion resistance is paramount, ASTM A269 stainless steel tubes find applications in transporting and containing corrosive fluids and gases.

Pharmaceutical industries demand hygienic and sterile environments. Stainless steel tubes complying with ASTM A269 are utilized in processes involving high-purity fluids and gases.

For the safe transport of food and beverages, ASTM A269 tubing ensures that no contaminants leach into consumable products.

Alloy 316/316L is an austenitic alloy and similar to 304/304L is used in a wide range of applications. It is an important alloy when it comes to chloride environments and many other chemical process industries. The addition of Molybdenum significantly increases general corrosion resistance as compared to 304/304L and more importantly, increases the chloride pitting resistance.

316/316L has excellent forming and welding characteristics. Due to its superior chloride pitting resistance, it is commonly used in applications involving chlorides or halides. That property is also useful in marine environments.

It also has an excellent resistance to intergranular corrosion in as-welded condition. Dual grade becomes important if heavy gauge welding is performed. This is where intergranular corrosion comes into picture and having a lower carbon version makes it difficult for Chromium Carbide to precipitate in the 797 to 1580 degF (425 to 860 degC) range when the welding is going on for a long time due to the heavy gauge.

It has excellent creep and rupture strength at higher temperatures compared to 304/304L. Finally, it has excellent strength and toughness at cryogenic temperatures.

In addition, it provides excellent elevated temperature tensile, creep and stress-rupture strengths.

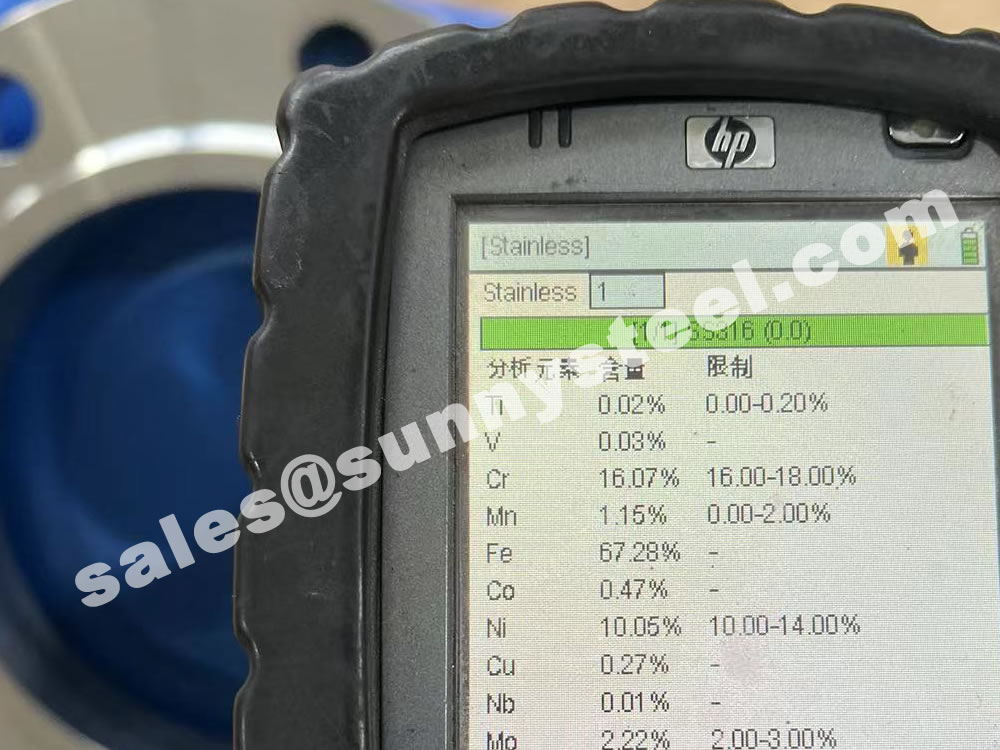

| Grade | 316 | 316L |

|---|---|---|

| UNS Designation | S31600 | S31603 |

| Carbon (C) Max. | 0.08 | 0.030* |

| Manganese (Mn) Max. | 2.00 | 2.00 |

| Phosphorous (P) Max. | 0.045 | 0.045 |

| Sulphur (S) Max. | 0.030 | 0.030 |

| Silicon (Si) Max. | 1.00 | 1.00 |

| Chromium (Cr) | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 | 2.0 – 3.0 |

| Nitrogen (N) | — | — |

| Iron (Fe) | Bal. | Bal. |

| Other Elements | — | — |

The main constituents of 316 stainless steel - other than iron - are Chromium and Nickel. However, it is the addition of 2% Molybdenum that provides the increased corrosion resistance.

316 contains 16 - 18% Chromium (Cr). Chromium is the essential chemical in all stainless steel and it is that which forms the thin passive layer that makes the metal "stainless"

316 also contains 10-14% Nickel (Ni). This is added to make the Austenitic structure more stable at normal temperatures.

The nickel also improves high-temperature oxidation resistance makes the steel resistant to stress corrosion cracking.

Where the steel is to be stretched formed a lower percentage (8%) of nickel should be selected. If the steel is to be deep drawn a higher percentage is better (9% or more).

In addition a number of other chemicals may be present but these are expressed as maximum permited levels with the exception of the increased quantity of carbon required in 316H - i.e. a minimum of .04% and a maximum of 0.10%

| Electrical Resistivity | Magnetic Permeability |

|---|---|

| 7.2e-005 ohm-cm | 1.008 |

| 7.2e-005 ohm-cm | 1.008 |

| at 20°C (68°F); 1.16E-04 at 650°C (1200°F) | at RT |

| Material | Form | Tensile Strength (ksi) |

Yield Strength (ksi) |

Elongation % |

Hardness HB |

|---|---|---|---|---|---|

| Alloy 316L | 316L Sheet AMS 5507 | 100 max | - | 45 | - |

| Alloy 316 | 316 Sheet AMS 5524 | 75 min | 30 | 45 | 207 max |

316/316L/316H stainless steel in the Annealed Condition at -20°F to +100°F

| Alloy | UNS Designation | Spec. | Tensile Strength (psi) | Tensile Strength (MPa) | Tensile Strength (ksi) | Yield Strength (psi) | Yield Strength (MPa) | Yield Strength (ksi) | Elongation in 2 inches (min.) % | Grain Size Req. | Max. Hardness | Modulus of Elasticity (x106 psi) | Mean Coefficient of Thermal Expansion (IN./IN./°F x 10-6) | Thermal Conductivity (BTU-in/ft2-h-°F) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 316 | S31600 | A249, A312 | 75,000 | 515 | 75 | 30,000 | 205 | 30 | 35 | — | 90 Rb | 28.0 | 9.2 | 116 |

| 316L | S31603 | A270, A312 | 70,000 | 485 | 70 | 25,000 | 170 | 25 | — | — | 90 Rb | 28.0 | 9.2 | 116 |

| 316H | S31609 | — | — | — | — | — | — | — | — | 7 or coarser | — | — | — | — |

| Alloy | UNS Designation | Werkstoff NR. | Specifications* |

|---|---|---|---|

| 316 | S31600 | 1.4401 | A269, A/SA249, A/SA312, A1016, A632, A/SA688 |

| 316L** | S31603 | 1.4404 | A269, A/SA249, A/SA312, A1016, A632, A/SA688 |

*Note: The specifications noted including ASTM, ASME, or other applicable authorities are correct at the time of publication. Other specifications may apply for use of these materials in different applications.

Type 316L is the low carbon version of 316 stainless. With the addition of molybdenum, the steel is popular for use in severe corrosion environments due to the materials immunity from boundary carbide precipitation (sensitisation).

The material is widely used in heavy gauge welded components and weld annealing is only required where the material is for use in high stress environments. 316L has an extensive variety of uses especially in marine applications due to the materials high corrosion resistance.

Type 316H is a higher carbon variant of 316 making the steel more suitable for use in applications where elevated temperatures are present.

Stabilised Grade 316Ti offers similar qualities.

The increased carbon content delivers a greater tensile and yield strength. The austenitic structure of the material also gives this grade excellent toughness, even down to cryogenic temperatures.

316 Stainless Steel is an austenitic stainless steel that is highly resistant to corrosion and oxidation. It is an alloy composed mainly of iron, with approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, along with small amounts of carbon, manganese, silicon, phosphorus, and sulfur. The addition of molybdenum differentiates it from 304 stainless steel, enhancing its resistance to pitting and crevice corrosion, especially in chloride environments.

For many industries, the choice of work surfaces is critical. When choosing an appropriate material, you must consider durability, cleanability, and longevity.

Stainless steel has long been a preferred choice for work surfaces because of its inherent strength and resistance to corrosion. However, not all stainless steel is created equal. With various grades available, understanding the specific properties of each is essential for making informed decisions.

304 stainless steel is the most common alloy used in everything from utensils to exhaust manifolds. However, certain applications require a more corrosive-resistant work surface. In those instances, we recommend 316 stainless steel.

Keep reading to learn more about 316 stainless steel, how it compares to 304 stainless steel, and why it is particularly suited for demanding environments such as labs, healthcare facilities, commercial kitchens, and beyond.

Stainless steel is a versatile and widely used material known for its exceptional strength, durability, and resistance to corrosion. At its core, stainless steel is an alloy primarily composed of iron, carbon, and chromium. It may also contain other elements such as molybdenum, nickel, manganese, and nitrogen.

It all starts with steel, which is formed by combining iron and carbon. This increases its overall hardness and, within specific ranges, boosts its strength (compared to iron). Steel typically contains up to 2% carbon and may include other elements to enhance its properties. These additions create various steel grades.

While steel is more durable than iron, it is still susceptible to oxidization when exposed to air and moisture.

Adding chromium to steel creates stainless steel, which is much better at resisting rust and high temperatures. The added chromium reacts with the oxygen in the air to form a passivated layer of chromic oxide. This layer serves as a protective barrier between the alloy and the environment, providing stainless steel with its renowned durability and wide temperature range.

Stainless steel is known for its exceptional properties, making it the preferred—and often required—work surfaces in various industries.

Here are some of the properties that make it a popular material:

Corrosion Resistance: Thanks to the chromium content, stainless steel forms a passive layer of chromic oxide that protects it from rust and corrosion. This layer can self-repair if damaged—if there is sufficient oxygen in the environment.

Heat Resistance: Maintains strength and resists scaling at high temperatures. Its melting point ranges from 2,550 to 2,790 °F (1,400 to 1,530 °C), depending on the grade and alloy composition.

Strength: Thanks to its alloy composition, stainless steel is a strong material, and its tensile yield strength varies depending on its alloys and whether it has been strengthened via cold working. Stainless steel provides excellent mechanical properties, making it suitable for heavy-duty applications and many manufacturing processes.

Aesthetic Appeal: Stainless steel has a sleek and modern appearance, which is both functional and aesthetically pleasing.

Cleanability: Besides looking clean, stainless steel has a smooth surface that is easy to clean and maintain. This contributes to its widespread use in hygienic applications such as healthcare facilities and clean room environments.

Stainless steel comes in different grades, each designed for specific uses and conditions depending on its composition and properties. The grades depend on their chemical content, physical properties, metallographic structure, and functional characteristics.

The mechanical properties fall into four families: ferrite, martensite, austenite, and duplex. These families are further categorized into grades describing the properties of the alloys used to produce them.

These variations in composition and processing result in unique physical properties, such as corrosion resistance, strength/durability, and magnetic behavior. Each change, adjustment, or addition to an alloy impacts the performance of a grade of stainless steel.

Understanding the differences between these grades is crucial for selecting the right material for your needs, as they are not all created equal.

When nickel is added, it is often called 300 Series stainless, the most widely used category of stainless steel. These grades are austenitic, meaning they have a face-centered cubic crystal structure that enhances their strength and corrosion resistance.

The presence of nickels, in addition to chromium, is a defining characteristic of this series, improving its overall performance. 300 Series alloys resist corrosion, maintain strength at high temperatures, and are easy to maintain.

The two most widely used grades of 300 Series stainless are 304 and 316.

Another common type of stainless steel is 400 Series stainless. These steels are martensitic and contain a higher carbon content, providing moderate magnetic properties. While these grades are known for their high strength and wear resistance, they offer less corrosion resistance than the 300 Series.

430 stainless steel is common in food service industries where less corrosion resistance is acceptable, providing a cost-effective option for certain applications.

While the 300 and 400 Series are the most common, other stainless steel grades are ideal for specialized applications.

200 Series stainless steels are austenitic and contain manganese and nitrogen instead of nickel, making them less expensive but also less corrosion-resistant than the 300 Series.

2205 Duplex Stainless Steel combines austenitic and ferritic properties. They contain higher levels of chromium, nickel, molybdenum, and nitrogen, which provide higher strength and excellent resistance to stress corrosion cracking.

300 Series stainless steel is known for its austenitic structure, which provides excellent mechanical properties and corrosion resistance. 304 and 316 stainless steel both contain high levels of chromium and nickel, which provides the material with excellent resistance to heat, abrasion, and corrosion. They also have excellent welding and forming properties, giving them applications in many industries. Both 304 and 316 stainless steels are considered surgical or medical-grade stainless steels and are considered the most common.

While similar, their compositional differences lead to distinct performance characteristics, making each suitable for specific applications. The most notable difference is the addition of molybdenum, which is in 316 but not 304. This alloy drastically enhances corrosion resistance, especially in more saline or chloride-exposed environments.

Contains approximately 18% chromium and 8% nickel.

Often referred to as 18/8 stainless steel.

Sometimes, it contains small amounts of carbon, manganese, and silicon.

Offers good corrosion resistance and is suitable for various environments, including exposure to chemicals and moisture.

Contains 16 - 18% chromium, 10 - 14% nickel, and 2 - 3% molybdenum.

The addition of molybdenum significantly enhances its resistance to chlorides and other corrosive elements.

Provides superior corrosion resistance, especially against chlorides and other industrial solvents.

Offers slightly better overall strength, particularly at elevated temperatures, and is resistant to pitting and crevice corrosion.

Maintains stability and strength at higher temperatures.

While 304 and 316 stainless steels offer excellent corrosion resistance and durability, 316 provides an advantage in enhanced resistance to chlorides and other corrosive substances.

The presence of molybdenum and higher nickel content provides 316 stainless steel with higher resistance to a wide range of chemicals, including sulfuric acid, bromides, iodides, and fatty acids, at high temperatures. This makes 316 the preferred material for equipment and surfaces in industries where exposure to aggressive chemicals and frequent cleaning with caustic agents are common.

Many industries, ranging from food service and marine to chemical and pharmaceutical, are specifying 316 given its durability for more corrosive and frequent cleaning protocols. Cleanrooms face more frequent and caustic cleaning protocols, which require a material that can withstand harsh chemicals.

The product contact surface and equipment feet in contact with flooring are the most susceptible to caustic substances, including but not limited to cleaning agents such as bleach, ammonia-based cleaners, hydrogen peroxide, and Sporeklenz.

Because 316 is more robust to chloride exposure, it is often called marine-grade stainless steel as it stands up to the salt (sodium chloride) in seawater better than other stainless alloys.

316 stainless steel is one of the most widely used steel alloys in the world and is the second most common type of stainless steel on the market. Typically, stainless steels achieve an inoxidisable state by protecting the iron (Fe) molecules in their crystalline structures from interacting with gases and liquids. Metallurgists achieve this by increasing the volume of chromium (Cr) in the alloy, which actively migrates to the surface of the material to form a corrosion-resistant patina. This is enhanced in 316 stainless steels by a higher concentration of 2 - 3% molybdenum (Mo), which reduces the alloy's susceptibility to corrosion from acids, alkalis and chlorides.

There are two primary grades of 316 stainless steel: low carbon and high carbon. This blog post explores the properties and applications of each in more detail.

Standard 316 stainless steels can also be characterised as low carbon alloys due to their minimal carbon content (~0.08%). Increasing the molybdenum content at the expense of carbon greatly reduces the risk of carbide precipitation at grain boundaries during welding and forming, which can inhibit the corrosion resistant properties of the alloy's substrate.

316 stainless steels originated as the ideal alloy for the pulp and paper industry due to its immunity to sulphur (S) compounds. It was gradually adopted for marine applications due to its superior resistance to chloride solutions such as seawater of varying salinity, and is still widely regarded as a marine grade alloy.

Although not identical, 316L stainless is very similar to standard 316 stainless and the two are often dual certified. 316H stainless cannot be certified in the same bracket as standard 316 stainless due to its higher carbon content (<0.10%). This confers greater thermo-mechanical properties, including higher operating temperatures and an average tensile strength of 515MPa.

316 stainless steel work surfaces are highly prized for their exceptional properties, making them ideal for many demanding applications. If you're looking for a surface material that provides superior corrosion resistance (particularly against chlorides and aggressive chemicals) and outstanding durability and strength, in addition to a smooth, easy-to-clean surface, 316 is a premium option.

Cleanrooms, pharmaceutical manufacturing, biopharma facilities, vivarium facilities, and laboratories require sterile, durable, and corrosion-resistant surfaces. 316 stainless steel work surfaces provide the necessary resistance to aggressive chemicals and frequent sterilization procedures.

In healthcare environments, 316 stainless steel work surfaces may be preferred in pharmacies and operating rooms (OR) because they offer unparalleled hygiene and durability. Their enhanced resistance to corrosion from exposure to various chemicals and cleaning agents makes them suitable for sterile work areas, and their smooth surface helps prevent contamination and supports the rigorous cleaning protocols necessary in healthcare settings.

In addition to withstanding caustic chemicals in lab and healthcare environments, 316 stainless steel is also beneficial when dealing with acidic materials, such as tomato sauce, and organic materials, like meat processing facilities or even butcher shops. Additionally, as a "marine grade" stainless steel, 316 is ideal for kitchens and food prep areas near the sea or on ocean-going vessels, where exposure to seawater is inevitable.

When comparing 304 and 316 stainless steel, the latter is undoubtedly more expensive, which can cause some hesitation, especially if it puts a project over budget. However, although 316 stainless steel worktops are more expensive to purchase than their 304 counterparts, the total cost of ownership is significantly lower due to their improved longevity and durability.

316 offers superior corrosion resistance for environments that require it, reducing the need for frequent replacements and repairs and offering long-term savings. When deciding whether you need 316 or if 304 will suffice, consider your specifications, your environment and your cleaning supplies - all of which will help you decide whether or not to invest in a 316 stainless steel worktable.

Stainless Steel 316 or 316L SS is a Chromium-Nickel stainless steel with added molybdenum to increase corrosion resistance and mechanical properties. It is non-magnetic in the annealed condition and not hardenable by heat treatment.

Our stainless steel bar stock lengths range from the industry standard 12' to 28' long. For projects requiring long length stainless steel bar, our inventory ranges from 20’-28’ R/L.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.