Nipo Flange

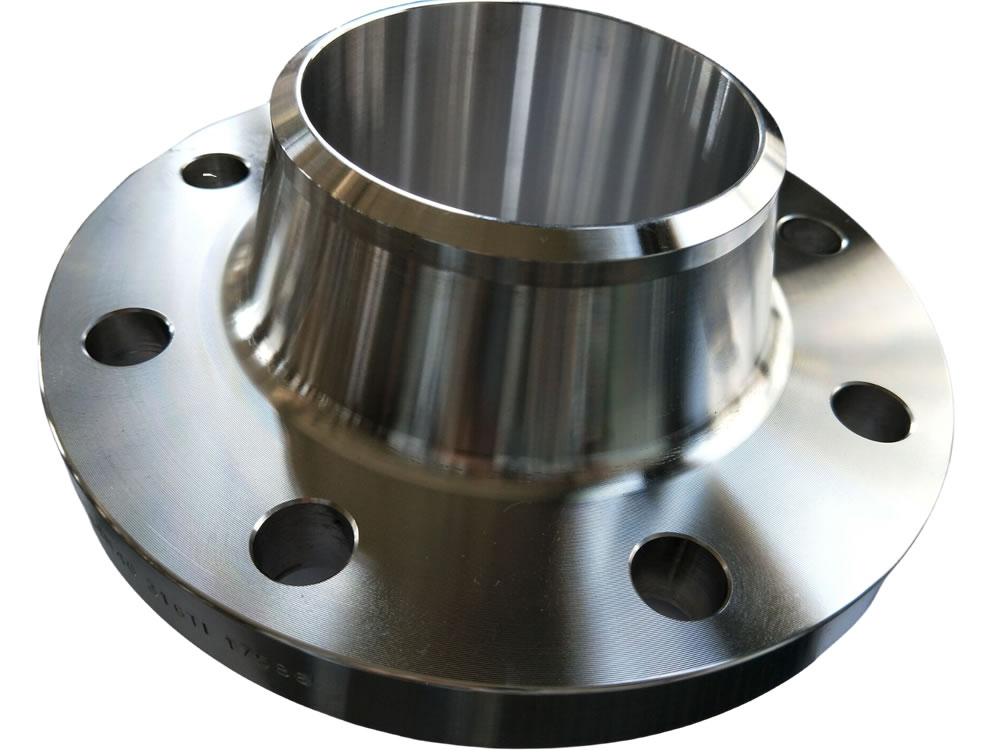

Nipoflange is a connection that has a flange on one side and a Nipolet on the other side.

Stainless steel flange is made from stainless steel, a corrosion-resistant alloy that is known for its strength, durability, and aesthetic appeal.

Stainless steel flanges come in various grades, such as 304, 304L, 316, 316L, and 310, each with its own specific properties and applications.

You want to get value for your money. Here is why stainless steel flanges are worth the investment.

In every metal application, corrosion is an important consideration. In the U.S., around $9 billion goes to handling pipeline corrosion incidences. Metals are acted upon by rust, chemicals, as well as other environmental factors. Therefore, it would be best if you chose flanges that can withstand these factors. Stainless steel becomes a perfect choice since it has a high resistance to corrosion.

Stainless steel is durable and can withstand a lot of pressure. Although aluminum could be a cheaper option, it cannot withstand as much stress.

In industries, the temperatures could get a bit extreme. However, stainless steel flange fittings can withstand the temperatures without deformation or warping. Therefore, at no point will your system be compromised.

Stainless steel flange simplified as SS flange, it refers to the flanges that made of stainless steel. It is a mechanical component used primarily in piping systems to connect two sections of pipe or other equipment, providing a robust and reliable junction.

The common material standards and grades for stainless steel are ASTM A182 Grade F304/L and F316/L, with pressure ratings ranging from Class 150 to Class 2500. Stainless steel is utilized in more industries than carbon steel because it offers superior corrosion resistance and an aesthetically pleasing appearance.

Generally they could be called stainless steel pipe flange, or stainless steel plate flange.

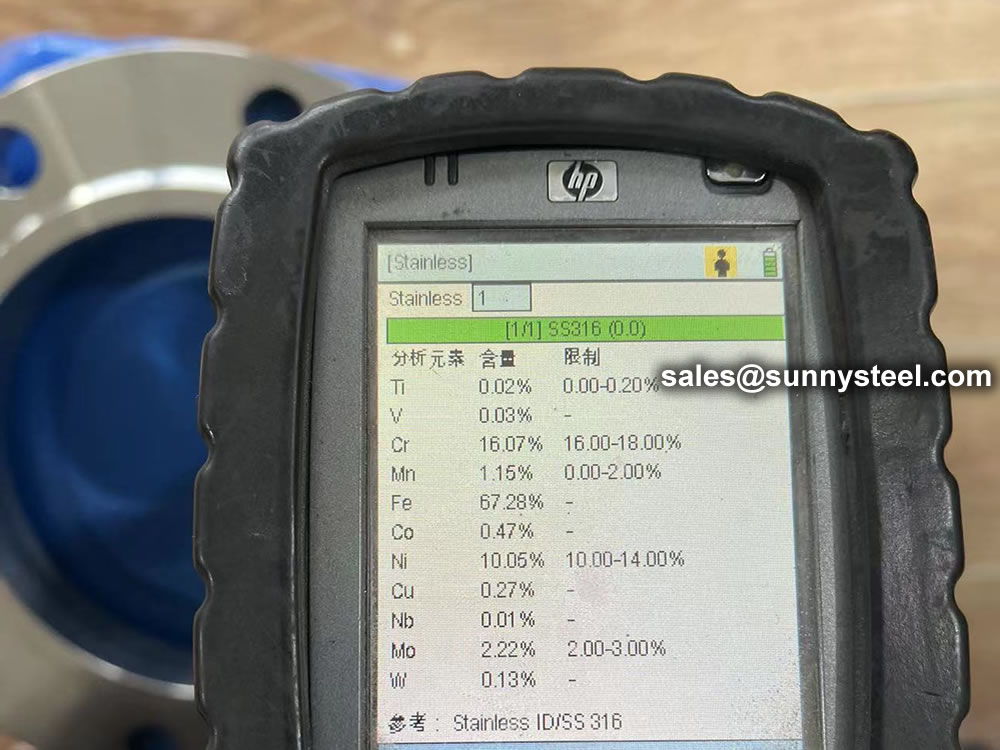

In metallurgy, stainless steel also called as inox steel or inoxidizable steel. It is a steel material alloyed with high content of chromium and nickel, where

As we know, stainless steel flange is impressed by it's great corrosion resistance, which because of the elements of Chromium, and as Cr increased, better resistant performances will be gained.

On the other hand, additions of Molybdenum will increase corrosion resistance in reducing acids and against pitting attack in chloride solutions. So there are different grades of stainless steel with varying Cr and Mo compositions to suit the environment with required to be alloyed.

For stainless steel pipe flange, common use material is ASTM A182 F304/L and F316/L.

ASTM A182: It refers to forged and rolled alloy and stainless steel pipe flanges, fittings, valves and parts for high temperature service. And it includes several grades of austenitic and ferritic-austenitic stainless steels.

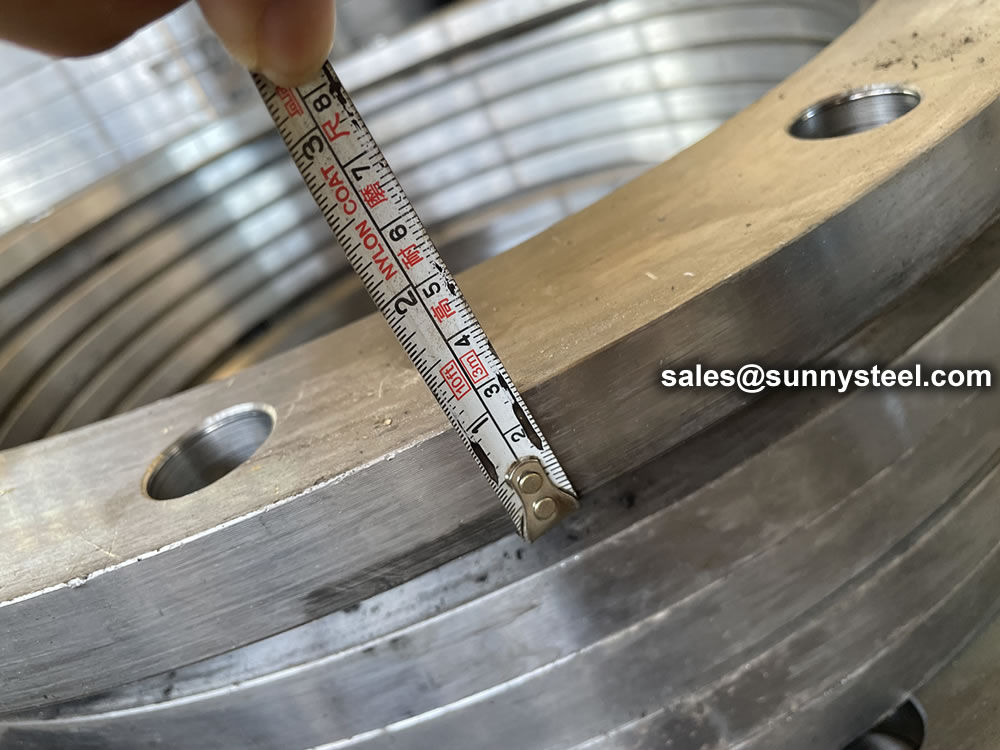

Dimensions: 1/2'' to 2'', 3'', 4'', 6'' and up to 48''.

Wall thickness schedule: SCH 10S, SCH 40S, SCH STD, SCH 80S

Pressure ratings: 150#, 300#, 600#, 900#, 1500#, 2500#

Material Grade: F304, F316, F321 and more

Corrosion resistant stainless steel flanges as the superior commodity choice.

This is the most common grade of stainless steel. 18% Cr, 8% Ni, nonmagnetic. We provide dual grade material that has the weldability that low carbon content improves as well as the higher rating of straight 304. Do note that in high temperature applications (over 800degF), 304H would be recommended.

This is the most common grade of stainless steel after 304/L, though due to certain industry demands, 316/L may more readily available. 18% Cr, a minimum of 10% Ni, with Molybdenum added, 316 provides superior corrosion resistance compared to 304. We provide dual grade material that has the weldability that low carbon content improves as well as the higher rating of straight 316. Do note that in high temperature applications (over 800degF), 316H would be recommended.

A high carbon variant of the most commonly used and extremely versatile stainless steel in the flange industry. 304H is an austenitic chromium stainless which contains a carbon content range of .04 – .10 to help with heat resistance for high temperature applications. It also carries all the general attributes and service properties of regular grade 304 stainless steel.

Similar in approach to 304H, grade 316H is a high carbon variant of regular grade 316 stainless steel, which contains a small percentage of molybdenum for use in marine grade applications.

This austenitic grade of stainless utilizes a higher carbon content for use in higher temperature service, much like its cousin grade 304H. Though it is less commonly used, it is still commercially available.

An austenitic chromium grade containing molybdenum, and similar to grade 316, except with a higher value of stress resistance, increased tensile strength, higher service in elevated temperature, and general resistance to corrosion from chloride, sulfuric solutions, or other corrosive media. The low carbon option (L) can be selected for a more optimal weld requirement.

A stainless grade with excellent workability, utilized in heat exchanger applications and projects with elevated temperatures involving high salinity. This grade contains an increased chromium and nickel content and has elevated characteristics of oxidation and corrosion resistance when compared to more common stainless grades such as 304 and 309.

An austenitic grade stainless containing over 4 or 5 times the level of titanium as it does in carbon, with a maximum titanium value of 0.70%. This material has a high intergranular corrosion resistance and is well utilized in high heat applications in the aerospace industry such as aircraft jet engine manifolds and exhaust components.

A stainless grade containing a small percentage of columbium and tantalum for stabilization purposes. Commonly used in the combined high heat and corrosion environments of refineries, power generation, and airline service, this austenitic alloy retains better properties in corrosive environments compared to similar alloys 321 and 317.

A corrosion resistant material category containing a minimal nickel content, and just enough chromium to reduce oxidation. Popular grades under the A182 spec include F11, F22, F5, and F9.

Can’t decide between stainless and alloy? How about the best of both worlds? We offer a variety of duplex in both forged and plate forms including grades 2205, F51, F53, and F60.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China,GB | Japan | American | Korea | EUR | Indai | Australia | Tai Wan | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New(07.10) | JIS | ASTM | UNS | KS | BS EN | IS | IS | CNS | |

| Austenitic stainless steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | 202 | |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | -02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.455 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic ferritic stainless steel (duplex stainless steel) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | - | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | - | 329J3L | 329J3L |

| 0Cr18Ni10Ti Iron type stainless steel | ||||||||||

| 25 | 0Crl3Al | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | - | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | - | - | STS410L | - | - | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 |

| 30 | - | 022Cr18NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | - | 444 | 444 |

| Martensitic stainless steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | - | - | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | - | - | STS420J2 | 1.4028 | 30 Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | - | - | 440A | 440A |

Stainless steel flanges are essential in industries like beverage, food, water, gas, and transport.

It also provides several benefits, a few of these including: Corrosion and stain resistance: Stainless steel flanges are excellent in a wide range of atmospheric environments and many corrosive media.

Stainless steel flanges are used to join pipes in oil and gas pipelines, as well as in water treatment and chemical processing.

Stainless steel flanges are used to connect pipes and valves in pressure vessels, such as boilers and tanks.

Stainless steel flanges are used in the food and beverage industry because of their hygienic properties.

Stainless steel flanges are used in shipbuilding because they resist saltwater corrosion.

Stainless steel flanges are used in power plants to connect pipes and valves in critical systems.

Stainless steel flanges are used in aircraft and aerospace applications because they are strong and resistant to extreme temperatures.

Stainless steel flanges are used in construction to connect pipes in HVAC systems, plumbing, and fire protection systems.

The most frequently asked questions regarding flanges and flange fittings have to do with how flanges fit on specific steel tube and steel pipe ends.

Stainless steel flanges are flanges made from stainless steel, which is a steel alloy that contains chromium and other metals that give it superior corrosion resistance.

Stainless steel flanges are strong, durable, and highly corrosion-resistant. They are also non-magnetic and hygienic.

Stainless steel flanges should be used in applications where high corrosion resistance is required, such as in the chemical, food processing, and pharmaceutical industries.

Stainless steel flanges are more expensive than other types of flanges, so they should not be used in applications where cost is a major consideration and where corrosion resistance is not required.

Stainless steel flanges are available in various types, including slip-on flanges, threaded flanges, weld neck flanges, and socket weld flanges.

Steel flanges must be packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet, iron & steel cage, iron & steel pallet etc.

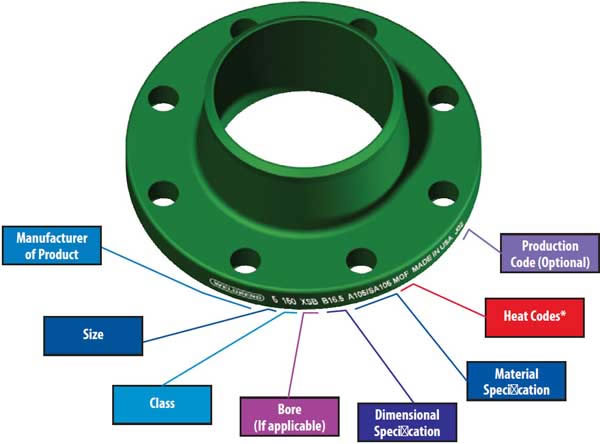

Flange markings are governed by ANSI ASME codes. Flange marking includes;

ASME B16.5 and B16.47 standards cover permissible tolerances for inspection.

Because of the normal wooden boxes or wooden pallets have to do fumigation treatment, we usually use plywood pallet or plywood case or box to pack steel flanges without fumigation treatment.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications.

We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.