316 Stainless Steel Elbow

Designed for durability and corrosion resistance, making them ideal for various industrial applications.

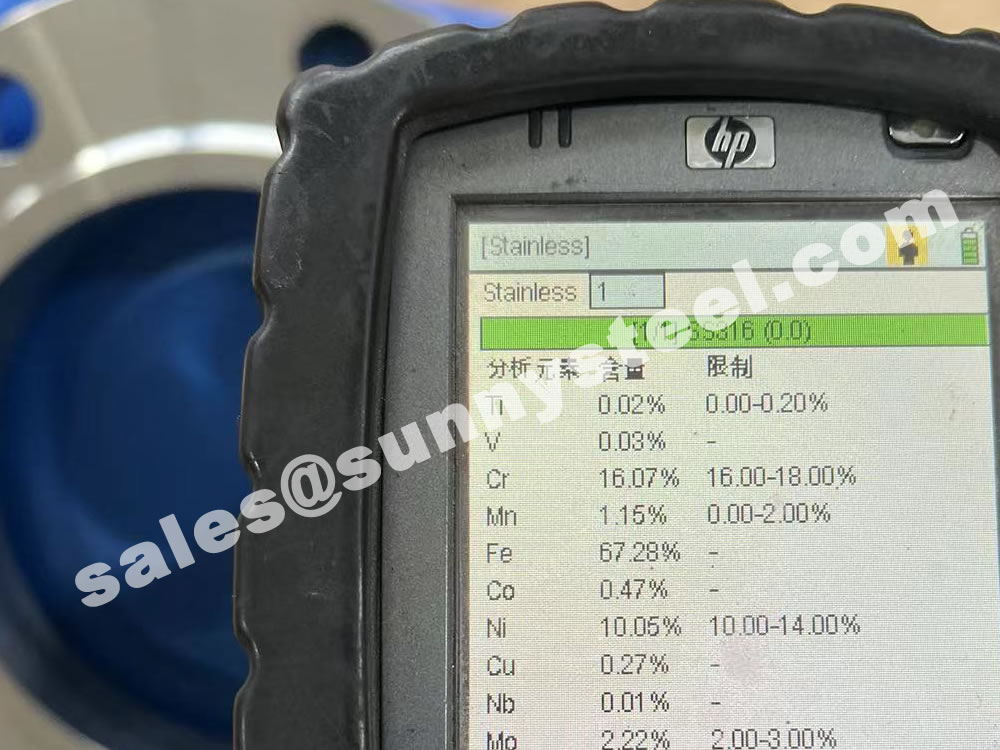

316 stainless steel plate is a type of austenitic stainless steel that contains 16% to 18% chromium, 10% to 14% nickel, and 2% to 3% molybdenum.

316 Stainless Steel Plate is a high-performance material known for its exceptional corrosion resistance, especially against chlorides and acids. This austenitic stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which enhance its strength, durability, and resistance to pitting and crevice corrosion. 316 stainless steel plates are widely used in industries such as chemical processing, marine, food processing, and pharmaceuticals due to their ability to withstand harsh environments. It also maintains its mechanical properties at high temperatures and is suitable for welding.

When it comes to high-quality stainless steel plates, 316 stainless steel plate stands out as a top contender. This remarkable material offers exceptional properties that make it indispensable in a wide range of industries and applications.

One of the key features of 316 stainless steel plate is its outstanding corrosion resistance. It can withstand exposure to harsh environments, including saltwater and aggressive chemicals, without succumbing to rust or degradation. This makes it ideal for marine applications, chemical processing plants, and outdoor structures where durability is paramount.

The mechanical properties of 316 stainless steel plate are also highly impressive. It possesses excellent strength and toughness, allowing it to withstand heavy loads and mechanical stress. Whether used in construction, manufacturing, or aerospace, this plate ensures reliable performance and long service life.

In addition to its durability and strength, 316 stainless steel plate offers good formability. It can be easily fabricated into various shapes and sizes, enabling designers and engineers to create complex components and structures with precision.

The aesthetic appeal of 316 stainless steel plate should not be overlooked. Its sleek and polished surface gives it a modern and sophisticated look, making it a preferred choice in architectural and decorative applications.

When choosing 316 stainless steel plate, it is essential to source it from a reliable supplier to ensure its quality and compliance with industry standards. A high-quality 316 stainless steel plate will provide you with peace of mind, knowing that your project or equipment is built to last.

Corrosion Resistance: One of the most significant features of 316 stainless steel is its enhanced resistance to chloride and other corrosive agents. The addition of molybdenum improves its performance in marine environments and chemical processing applications, making it more resistant to pitting and crevice corrosion than the 304-grade steel.

High-Temperature Resistance: 316 stainless steel can withstand temperatures up to 1500°F, making it ideal for applications involving heat exchangers, boilers, and other high-temperature equipment.

Strength and Durability: With a tensile strength of around 515 MPa and excellent resistance to wear and tear, 316 stainless steel plates are perfect for demanding mechanical environments.

Marine Industry: Due to its outstanding resistance to saltwater, 316 stainless steel is widely used in shipbuilding, marine fasteners, and offshore platforms.

Chemical Processing: Its resistance to corrosive chemicals makes it a preferred material for storage tanks, piping systems, and valves in chemical plants.

Medical and Pharmaceutical Equipment: Biocompatibility and ease of sterilization make it suitable for surgical instruments and implants.

Food and Beverage Industry: Non-reactive and easy to clean, it is used in food processing equipment and brewing tanks.

Construction and Architecture: Its aesthetic appeal and long-lasting durability make it popular in architectural projects, such as facades and structural components.

Longevity: With low maintenance requirements and superior resistance to environmental factors, 316 stainless steel plates offer long-term durability.

Versatility: Whether in the medical field, marine applications, or industrial processing, 316 stainless steel can be adapted for various uses.

Cost-Effective: Although it may come with a higher upfront cost compared to other materials, its durability and low maintenance make it a cost-effective choice in the long run.

316 stainless steel plates stand out for their excellent performance in corrosive environments, high durability, and versatility across multiple industries. For applications where strength, resistance to harsh conditions, and longevity are crucial, 316 stainless steel is an ideal choice.

Alloy 316/316L is an austenitic alloy and similar to 304/304L is used in a wide range of applications. It is an important alloy when it comes to chloride environments and many other chemical process industries. The addition of Molybdenum significantly increases general corrosion resistance as compared to 304/304L and more importantly, increases the chloride pitting resistance.

316/316L has excellent forming and welding characteristics. Due to its superior chloride pitting resistance, it is commonly used in applications involving chlorides or halides. That property is also useful in marine environments.

It also has an excellent resistance to intergranular corrosion in as-welded condition. Dual grade becomes important if heavy gauge welding is performed. This is where intergranular corrosion comes into picture and having a lower carbon version makes it difficult for Chromium Carbide to precipitate in the 797 to 1580 degF (425 to 860 degC) range when the welding is going on for a long time due to the heavy gauge.

It has excellent creep and rupture strength at higher temperatures compared to 304/304L. Finally, it has excellent strength and toughness at cryogenic temperatures.

In addition, it provides excellent elevated temperature tensile, creep and stress-rupture strengths.

| Grade | 316 | 316L |

|---|---|---|

| UNS Designation | S31600 | S31603 |

| Carbon (C) Max. | 0.08 | 0.030* |

| Manganese (Mn) Max. | 2.00 | 2.00 |

| Phosphorous (P) Max. | 0.045 | 0.045 |

| Sulphur (S) Max. | 0.030 | 0.030 |

| Silicon (Si) Max. | 1.00 | 1.00 |

| Chromium (Cr) | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 | 2.0 – 3.0 |

| Nitrogen (N) | — | — |

| Iron (Fe) | Bal. | Bal. |

| Other Elements | — | — |

The main constituents of 316 stainless steel - other than iron - are Chromium and Nickel. However, it is the addition of 2% Molybdenum that provides the increased corrosion resistance.

316 contains 16 - 18% Chromium (Cr). Chromium is the essential chemical in all stainless steel and it is that which forms the thin passive layer that makes the metal "stainless"

316 also contains 10-14% Nickel (Ni). This is added to make the Austenitic structure more stable at normal temperatures.

The nickel also improves high-temperature oxidation resistance makes the steel resistant to stress corrosion cracking.

Where the steel is to be stretched formed a lower percentage (8%) of nickel should be selected. If the steel is to be deep drawn a higher percentage is better (9% or more).

In addition a number of other chemicals may be present but these are expressed as maximum permited levels with the exception of the increased quantity of carbon required in 316H - i.e. a minimum of .04% and a maximum of 0.10%

| Electrical Resistivity | Magnetic Permeability |

|---|---|

| 7.2e-005 ohm-cm | 1.008 |

| 7.2e-005 ohm-cm | 1.008 |

| at 20°C (68°F); 1.16E-04 at 650°C (1200°F) | at RT |

| Material | Form | Tensile Strength (ksi) |

Yield Strength (ksi) |

Elongation % |

Hardness HB |

|---|---|---|---|---|---|

| Alloy 316L | 316L Sheet AMS 5507 | 100 max | - | 45 | - |

| Alloy 316 | 316 Sheet AMS 5524 | 75 min | 30 | 45 | 207 max |

316/316L/316H stainless steel in the Annealed Condition at -20°F to +100°F

| Alloy | UNS Designation | Spec. | Tensile Strength (psi) | Tensile Strength (MPa) | Tensile Strength (ksi) | Yield Strength (psi) | Yield Strength (MPa) | Yield Strength (ksi) | Elongation in 2 inches (min.) % | Grain Size Req. | Max. Hardness | Modulus of Elasticity (x106 psi) | Mean Coefficient of Thermal Expansion (IN./IN./°F x 10-6) | Thermal Conductivity (BTU-in/ft2-h-°F) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 316 | S31600 | A249, A312 | 75,000 | 515 | 75 | 30,000 | 205 | 30 | 35 | — | 90 Rb | 28.0 | 9.2 | 116 |

| 316L | S31603 | A270, A312 | 70,000 | 485 | 70 | 25,000 | 170 | 25 | — | — | 90 Rb | 28.0 | 9.2 | 116 |

| 316H | S31609 | — | — | — | — | — | — | — | — | 7 or coarser | — | — | — | — |

| Alloy | UNS Designation | Werkstoff NR. | Specifications* |

|---|---|---|---|

| 316 | S31600 | 1.4401 | A269, A/SA249, A/SA312, A1016, A632, A/SA688 |

| 316L** | S31603 | 1.4404 | A269, A/SA249, A/SA312, A1016, A632, A/SA688 |

*Note: The specifications noted including ASTM, ASME, or other applicable authorities are correct at the time of publication. Other specifications may apply for use of these materials in different applications.

Type 316L is the low carbon version of 316 stainless. With the addition of molybdenum, the steel is popular for use in severe corrosion environments due to the materials immunity from boundary carbide precipitation (sensitisation).

The material is widely used in heavy gauge welded components and weld annealing is only required where the material is for use in high stress environments. 316L has an extensive variety of uses especially in marine applications due to the materials high corrosion resistance.

Type 316H is a higher carbon variant of 316 making the steel more suitable for use in applications where elevated temperatures are present.

Stabilised Grade 316Ti offers similar qualities.

The increased carbon content delivers a greater tensile and yield strength. The austenitic structure of the material also gives this grade excellent toughness, even down to cryogenic temperatures.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.