U-Shaped Snap Ring

U-shaped snap rings are versatile and reliable components essential for securing parts in various mechanical assemblies.

Discover the design, applications, and installation methods of U-shaped snap rings, versatile retaining rings used in various industries for securing components onto shafts or within bores.

Download PDF

A U-shaped snap ring is a type of retaining ring that features a U-shaped design. It is used to secure components onto shafts or inside bores, preventing lateral movement or displacement. The U-shape allows for flexibility and easy installation or removal, making it a popular choice in various mechanical applications where securing components without the use of fasteners or adhesives is essential.

The inner diameter of the U-shaped snap ring is the outer diameter of the wear-resistant tile plus the thickness of the wear-resistant tile, and the length varies from 20mm to 70mm. It will be 5mm more in semicircle. The extra part during installation will hold the wear-resistant tile and then spot weld. Compared with the butt-type semicircular snap ring, it is stronger after holding the wear-resistant tile and welding.

They are particularly useful in confined spaces and offer a spring-like action for easy installation and removal. Commonly used in securing erosion shields in boilers and heat exchangers, these rings are made from high-strength materials like spring steel and stainless steel to ensure durability and reliability.

The U-shaped profile provides a spring-like action that allows the snap ring to compress when installed and expand to secure the component in place.

Unlike standard round snap rings, the U-shape allows for more flexibility and easier installation, particularly in confined spaces.

While some U-shaped snap rings can be installed manually, specialized tools are available to ensure proper placement without damaging the ring or associated components. These tools include:

U-shaped snap rings are versatile and reliable components essential for securing parts in various mechanical assemblies. Understanding their design, applications, advantages, and the appropriate installation methods ensures optimal performance and longevity in their respective applications.

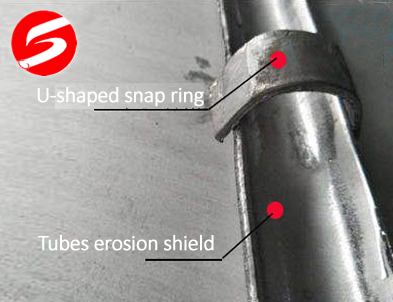

Snap rings are used in conjunction with boiler tubes erosion shields, which is a clip that easily installs boiler tubes erosion shields to the tube.

The snap ring and Boiler Tubes Erosion Shields are overlapped and welded, generally about 190-200 degrees Erosion Shields is a 180-degree semicircle), but also leave a welding position for easy welding and fixing. Generally, each piece of Boiler Tubes Erosion Shields needs to be equipped with 2-4 snap rings with a pitch of 200-500mm.

The anti-wear snap ring is also called clamp, buckle, tube clamp, etc.

The main role of the anti-wear tile snap ring: the role of fixing the anti-wear tile to avoid problems such as the anti-wear tile falling off during installation.

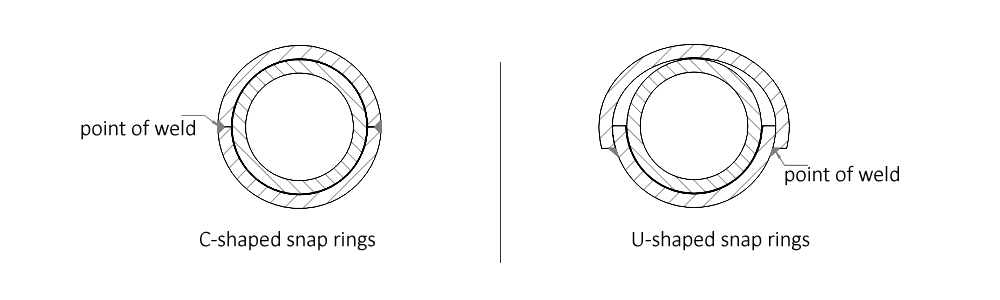

The types of common anti-wear tile rings can be divided into: U-shaped lap type snap ring, butt-type semicircular snap ring.

All products are purchased to proprietary customized specifications as well as normal industry standards with supporting documentation.

The inner diameter of the U-shaped snap ring is the outer diameter of the wear-resistant tile plus the thickness of the wear-resistant tile, and the length varies from 20mm to 70mm. It will be 5mm more in semicircle. The extra part during installation will hold the wear-resistant tile and then spot weld. Compared with the butt-type semicircular snap ring...

C-shaped snap ring is the most common snap ring. Mainly based on the size of anti-friction tile, the diameter and thickness are similar to the matching anti-friction tile, and the length varies from 20mm to 70mm. It is mainly connected to the wear-resistant tile by spot welding when installing the wear-resistant tile, so as to fix and prevent the wear-resistant tile from falling off.

Custom snap rings are the recommended method for tube shield attachment.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.