Erosion Shields

Erosion Shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Boiler Tubes Erosion Shields protect pipes from erosion and corrosion. Discover specifications, materials, and advanced manufacturing processes.

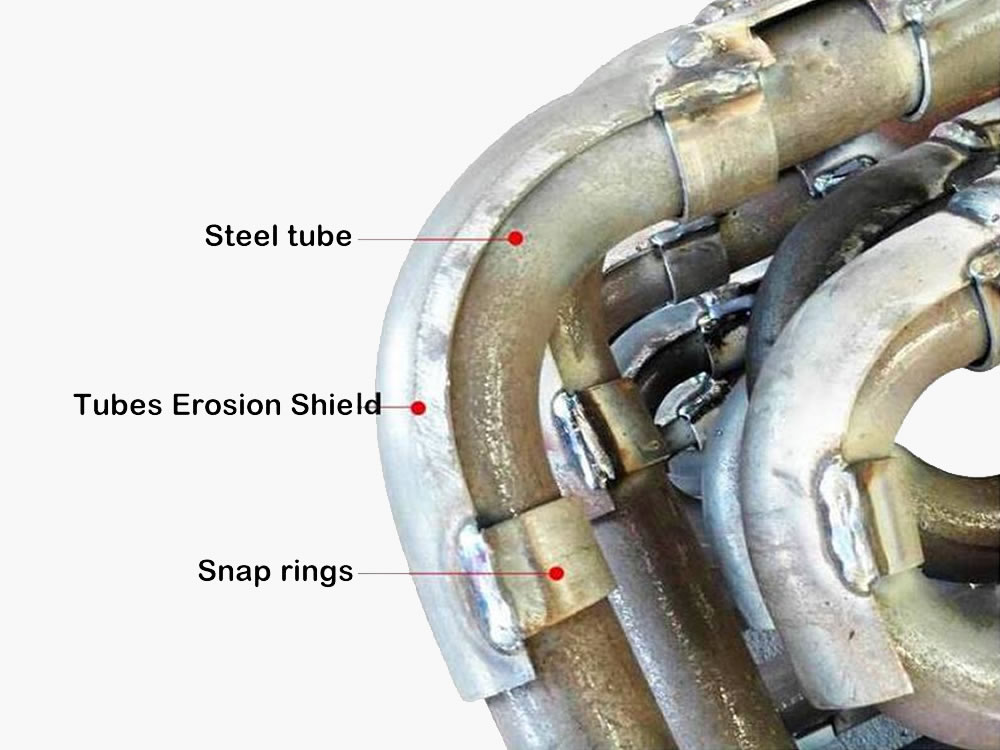

Download PDFBoiler Tubes Erosion Shields, also known as anti-corrosion shields or anti-wear plates, are essential for protecting boiler tubes from erosion and corrosion. Commonly used in combination with snap rings, they ensure durability and reliability in harsh industrial environments.

These shields are produced using high-pressure presses and professional mold pressing techniques. The production process ensures a smooth surface, excellent welding performance, and aesthetic appeal. Boiler Tubes Erosion Shields with bends are created using specialized abrasives or presses for precision shaping.

Processing Thickness: Boiler Tubes Erosion Shields are available in thicknesses of 2mm, 3mm, 4mm, and 5mm. The selection depends on the severity of wear and heat conduction requirements.

Shapes and Specifications: The cross-sectional shape is primarily semi-circular (180 degrees) but may range from 120 to 160 degrees for specific applications, such as finned tubes or water-cooled walls. Types include direct wear-resistant shields, inner-curve shields, outer-curve shields, side-curve shields, and S-curve shields. Straight shields range from 20mm to 3000mm in length, with 1000-2000mm being the most common. For curved shields, processing drawings should specify pipe diameter, bend radius, angle, and straight section lengths.

Tube Compatibility: Shield diameters typically range from 32mm to 89mm, with the inner diameter being 1-3mm larger than the tube's outer diameter for optimal fitting. Popular sizes include 38.1mm, 44.5mm, 50.8mm, 57.15mm, and 63.5mm.

Erosion shields can be manufactured from various materials, including mild steel, chrome moly steel, stainless steel, and exotic alloys like Inconel. Popular options include 3mm stainless steel grade 304 and 2mm UNS S30815 (Sandvik grade 253MA). Certified materials meet standards such as A387 P11, P22 chrome moly, and A240TP304, 316, and 309 stainless steel. Hard-wearing chromium carbide coatings are available for enhanced durability.

Boiler Tubes Erosion Shields are vital in industries such as power generation, petrochemicals, and manufacturing. They are designed to extend the lifespan of boiler tubes, reduce maintenance costs, and ensure uninterrupted operations.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.