JIS 3101 SS400 steel plate is a high-quality carbon steel widely used in structural and general engineering applications.

It is known for its weldability, formability, and strength, suitable for construction, bridges, and ships. Learn more about SS400 steel plate specifications and applications.

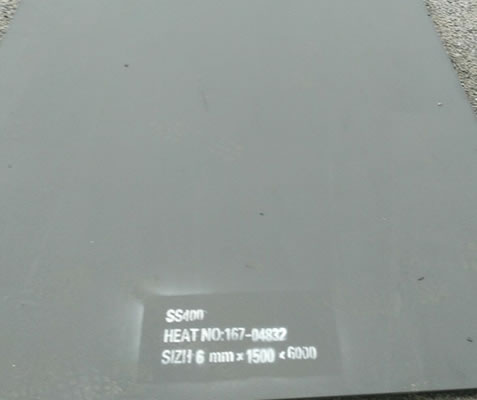

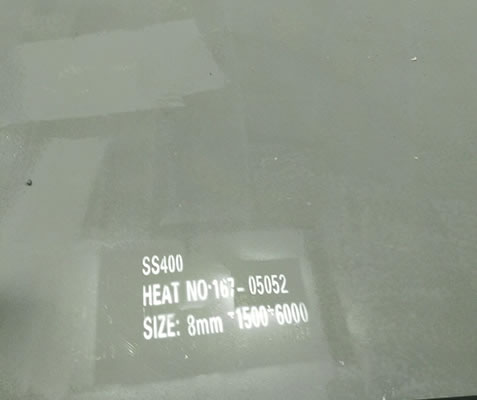

Steel Structural 400 grade, or SS400, is defined by the Japanese material standard JIS G 3101 for hot rolled steel plates, sheets, and strips used in general structural applications. SS400 is primarily utilized in the engine parts industry due to its low carbon content and a minimum tensile strength limit of 400 MPa. At Conquest Steel & Alloys, we manufacture high-quality SS400 plates and supply them globally. The specifications of the plates vary based on surface finish, end finish, dimensions, shapes, sizes, and length, all of which can be tailored to meet customer requirements.

SS400 is a reliable structural rolled steel used to create a variety of plates and other components. The material's hot-rolled nature provides excellent tensile strength, making it ideal for numerous industrial applications. Additionally, the steel is versatile and forms the foundation for many different products beyond plates.

The SS400 alloy has various inherent characteristics that enhance its utility across a broad range of industries. Due to the presence of carbon, the plates exhibit good corrosion resistance. Silicon and chromium contribute to the material’s high tensile strength, durability, and flexibility. Moreover, SS400 plates offer excellent formability and weldability, which makes them valuable for a wide array of applications.

Conquest Steel & Alloys is committed to supplying high-quality SS400 plates developed according to international and national standards. Our plates meet a range of customer specifications and are shipped worldwide, ensuring the highest quality and performance for structural and engineering needs.

| Grade | Comparison of Steel Grades | |

|---|---|---|

| S400 JIS3101 | EN10025:1990 | FE 360 B |

| DIN17100 | ST37-2 | |

| NFA 35-501 | E24-2 | |

| EN 10025-2 | S235JR | |

| ASTM | A283C | |

| UNI7070 | FE 360 B | |

| Property | Value |

|---|---|

| Density and specific gravity, g/cm3 | 7.85 |

| Melting point, ℃ | 1494 - 1527 |

| Specific heat capacity, J/(Kg·K) | 473 at 20 ℃ |

| Electrical resistivity, μΩ·m | About 0.15 (20 ℃) |

| Long. elastic modulus, GPa | 206 |

| Tr. modulus of elasticity, GPa | 79 |

| Shear modulus, GPa | 79 |

| Thermal conductivity, (W/m·K) | 57 - 60 |

| Linear expansion coefficient, (10-6/K) | 11.3 - 11.6 (20 ℃) |

| Young’s modulus, GPa | 206 |

| Poisson’s ratio | 0.3 |

| Magnetic permeability, mm2/s | 13.9 |

| SS400 Steel Plate Thickness in mm. | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | 2.3 | 2.5 | (2.6) | 2.8 |

| (2.9) | 3.2 | 3.6 | 4.0 | 4.5 | 5.0 | 5.6 | 6.0 | 6.3 |

| 7.0 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 | 12.7 | 13.0 | 14.0 |

| 15.0 | 16.0 | (17.0) | 18.0 | 19.0 | 20.0 | 22.0 | 25.0 | 25.4 |

| 28.0 | (30.0) | 32.0 | 36.0 | 38.0 | 40.0 | 45.0 | 50.0 | |

| Material thickness tolerance in mm | ||||||

|---|---|---|---|---|---|---|

| Thickness (t) | Steel Plate width (W)<1600 | 1600≤ W <2000 | 2000≤ W <2500 | 2500≤ W <3150 | 3150≤ W <4000 | 4000≤ W <5000 |

| 4.00≤t<5.00 | ±0.45 | ±0.55 | ±0.55 | ±0.65 | – | – |

| 5.00≤t<6.30 | ±0.50 | ±0.60 | ±0.60 | ±0.75 | ±0.75 | ±0.85 |

| 6.30≤t<10.00 | ±0.55 | ±0.65 | ±0.65 | ±0.80 | ±0.80 | ±0.90 |

| 10.00≤t<16.00 | ±0.55 | ±0.65 | ±0.65 | ±0.80 | ±0.80 | ±1.00 |

| 16.00≤t<25.00 | ±0.65 | ±0.75 | ±0.75 | ±0.95 | ±0.95 | ±1.10 |

| 25.00≤t<40.00 | ±0.70 | ±0.80 | ±0.80 | ±1.00 | ±1.00 | ±1.20 |

| 40.00≤t<63.00 | ±0.80 | ±0.95 | ±0.95 | ±1.10 | ±1.10 | ±1.30 |

| 63.00≤t<100.00 | ±0.90 | ±1.10 | ±1.10 | ±1.30 | ±1.30 | ±1.50 |

| 100.00≤t<160.00 | ±1.30 | ±1.50 | ±1.50 | ±1.70 | ±1.70 | ±1.90 |

| 160.00≤t<200.00 | ±1.60 | ±1.80 | ±1.80 | ±1.90 | ±1.90 | ±2.10 |

| 200.00≤t<250.00 | ±1.80 | ±1.90 | ±1.90 | ±2.00 | ±2.00 | ±2.20 |

| 250.00≤t<300.00 | ±2.00 | ±2.10 | ±2.10 | ±2.20 | ±2.20 | ±2.50 |

| 300.00≤t≤350.00 | ±2.10 | ±2.30 | ±2.30 | ±2.40 | ±2.40 | ±2.80 |

| Standard width of steel plate and steel belt (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 600 | 630 | 670 | 710 | 750 | 800 | 850 | 900 | 914 | 950 |

| 1000 | 1060 | 1100 | 1120 | 1180 | 1200 | 1219 | 1250 | 1300 | 1320 |

| 1400 | 1500 | 1524 | 1600 | 1700 | 1800 | 1829 | 1900 | 2000 | 2100 |

| 2134 | 2438 | 2500 | 2600 | 2800 | 3000 | 3048 | |||

JIS G3101 SS400 is a widely used Japanese standard for structural carbon steel, known for its excellent weldability and machinability, making it suitable for a variety of structural applications.

| Element | Maximum Percentage (%) |

|---|---|

| Carbon (C) | 0.17% for thickness ≤ 16mm; 0.20% for thickness > 16mm |

| Manganese (Mn) | 1.60% |

| Phosphorus (P) | 0.050% |

| Sulfur (S) | 0.050% |

| TAIWAN - CNS | CHINA - GB | JAPAN - JIS | USA - ASTM | GERMANY - DIN |

|---|---|---|---|---|

| SS400 | Q235A, Q235B, Q235C, Q235D | SS400 | A570 Gr.30, A570 Gr.45, A 36/A283M Gr.D | St37-2, Ust37-2, RSt37-2 |

SS400 is extensively used in structural applications such as building frames, bridges, and other construction components due to its strength and weldability. Its versatility also makes it suitable for manufacturing parts that require bending, forming, or welding.

This steel grade exhibits good weldability and machinability, allowing for ease in fabrication and assembly in various structural projects.

While SS400 has modest corrosion resistance, it is often coated or painted to enhance its durability in corrosive environments.

When selecting SS400 or its equivalents for a project, it's essential to consider the specific requirements and standards applicable to ensure optimal performance and compliance.

Hot rolled steel plate is produced by hot rolling a slab of steel into a plate. It is used in the shipbuilding, pressure equipment and construction industries.

JIS G3101 is a Japanese standard for carbon steel used in general structural applications.

This standard covers several grades of steel, including SS330, SS400, SS490, and SS540, which are widely used in construction, bridges, ships, and other structural engineering projects. The steels specified under JIS G3101 provide excellent strength, toughness, and weldability, making them suitable for use in demanding environments. SS400 is the most commonly used grade due to its versatility and balance of strength and workability.

| JIS G3101 | Yield (≤16mm) | Yield (16 - 40mm) | Yield (40 - 100mm) | Yield (>100mm) | Tensile Strength |

|---|---|---|---|---|---|

| SS330 | ≥205Mpa | ≥195Mpa | ≥175Mpa | ≥165Mpa | 330 - 430Mpa |

| SS400/SS41 | ≥245Mpa | ≥235Mpa | ≥215Mpa | ≥205Mpa | 400 - 510Mpa |

| SS490 | ≥285Mpa | ≥275Mpa | ≥255Mpa | ≥245Mpa | 490 - 610Mpa |

| SS540 | ≥400Mpa | ≥390Mpa | - | - | ≥540Mpa |

| Grade | C | Mn | P | S |

|---|---|---|---|---|

| SS330/SS400/SS490 | - | - | ≤0.050 | ≤0.050 |

| SS540 | ≤0.30 | ≤1.60 | ≤0.040 | ≤0.040 |

| Standard | Grade | Grade | Grade | Grade |

|---|---|---|---|---|

| ASME SA36/ASTM A36 | A36 | |||

| ASME SA283/ASTM A283 | A283 Grade C | A283 Grade D | ||

| ASME SA572/ASTM A572 | A572 Grade 42 | A572 Grade 50 | A572 Grade 55 | A572 Grade 60 |

| ASME SA572/ASTM A572 | A572 Grade 65 | |||

| ASME SA573/ASTM A573 | A573 Grade 58 | A573 Grade 65 | A573 Grade 70 | |

| ASME SA633/ASTM A633 | A633 Grade A | A633 Grade C | A633 Grade D | A633 Grade E |

| ASME SA656/ASTM A656 | A656 Grade 50 | A656 Grade 60 | A656 Grade 70 | A656 Grade 80 |

| ASME SA656/ASTM A656 | A656 Grade 100 | |||

| EN10025-2 | S235JR | S235J0 | S235J2 | S275JR |

| EN10025-2 | S275J0 | S275J2 | S355JR | S355J0 |

| EN10025-2 | S355J2 | S355K2 | S450J0 | |

| EN10025-3 | S275N | S275NL | S355N | S355NL |

| EN10025-3 | S420N | S420NL | S460N | S460NL |

| EN10025-4 | S275M | S275ML | S355M | S420ML |

| EN10025-4 | S355ML | S460M | S420M | S460ML |

| EN10025-6 | S460Q | S460QL | S460QL1 | S500Q |

| EN10025-6 | S500QL | S500QL1 | S550Q | S550QL |

| EN10025-6 | S550QL1 | S620Q | S620QL | S620QL1 |

| EN10025-6 | S690Q | S690QL | S890Q | S690QL1 |

| EN10025-6 | S890QL | S890QL1 | S960Q | S960QL |

| JIS G3101 | SS330 | SS400 | SS490 | SS540 |

| JIS G3106 | SM400A | SM400B | SM400C | SM490A |

| JIS G3106 | SM490B | SM490C | SM490YA | SM490YB |

| JIS G3106 | SM520B | SM520C | SM570 | |

| JIS G4051 | S20C | S25C | S30C | S35C |

| JIS G4051 | S40C | S45C | S50C | S55C |

| JIS G4051 | S60C | S65C | S70C | S75C |

| DIN 17100 | St37-2 | USt37-2 | RSt37-2 | St37-3 |

| DIN 17100 | St52-3 | |||

| DIN 17102 | StE255 | WStE255 | TStE255 | EStE255 |

| DIN 17102 | StE285 | WStE285 | TStE285 | EStE285 |

| DIN 17102 | StE315 | WStE315 | TStE315 | EStE315 |

| DIN 17102 | StE355 | WStE355 | TStE355 | EStE355 |

| DIN 17102 | StE380 | WStE380 | TStE380 | EStE380 |

| DIN 17102 | StE420 | WStE420 | TStE420 | EStE420 |

| DIN 17102 | StE460 | WStE460 | TStE460 | EStE460 |

| DIN 17102 | StE500 | WStE500 | TStE500 | EStE500 |

| GB/T700 | Q195 | Q235A | Q235B | Q235C |

| GB/T700 | Q235D | Q275 | ||

| GB/T1591 | Q355B | Q355C | Q355D | Q390B |

| GB/T1591 | Q390C | Q420B | Q420C | Q460C |

| GB/T1591 | Q390N | Q420N | Q460N | Q390M |

| GB/T1591 | Q420M | Q460M | Q550M | Q620M |

| GB/T1591 | Q690M | |||

| GB/T16270 | Q460C | Q460D | Q460E | Q460F |

| GB/T16270 | Q500C | Q500D | Q500E | Q500F |

| GB/T16270 | Q550C | Q550D | Q550E | Q550F |

| GB/T16270 | Q620C | Q620D | Q620E | Q620F |

| GB/T16270 | Q690C | Q690D | Q690E | Q690F |

| GB/T16270 | Q800C | Q800D | Q800E | Q800F |

| GB/T16270 | Q890C | Q890D | Q890E | Q890F |

| GB/T16270 | Q960C | Q960D | Q960E | Q960F |

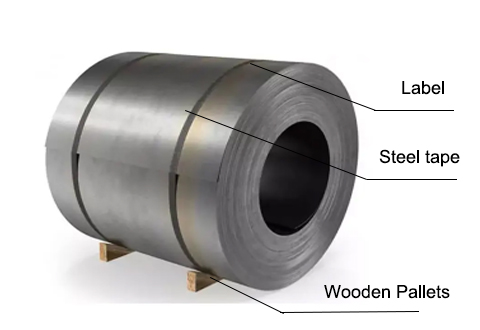

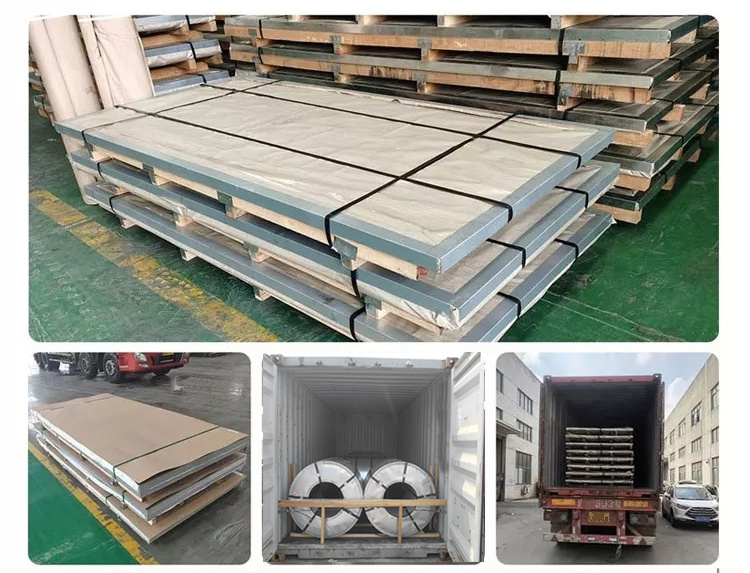

By bundles, each bundle weight under 3 tons, for small outer Diameter round bar, each bundle with 4 - 8 steel strips.

20 feet container contains dimension, length under 6000mm

40 feet container contains dimension, length under 12000mm

By bulk vessel, Freight charge is low by bulk cargo, and large Heavy sizes can not be loaded into containers can shipping by bulk cargo

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.