Bimetal hardfacing wear plates are designed to provide superior wear resistance in highly abrasive environments.

These plates consist of a base layer of mild steel or stainless steel, onto which a hard, wear-resistant alloy is deposited through welding or other metallurgical processes. This combination results in a composite material with enhanced durability and service life.

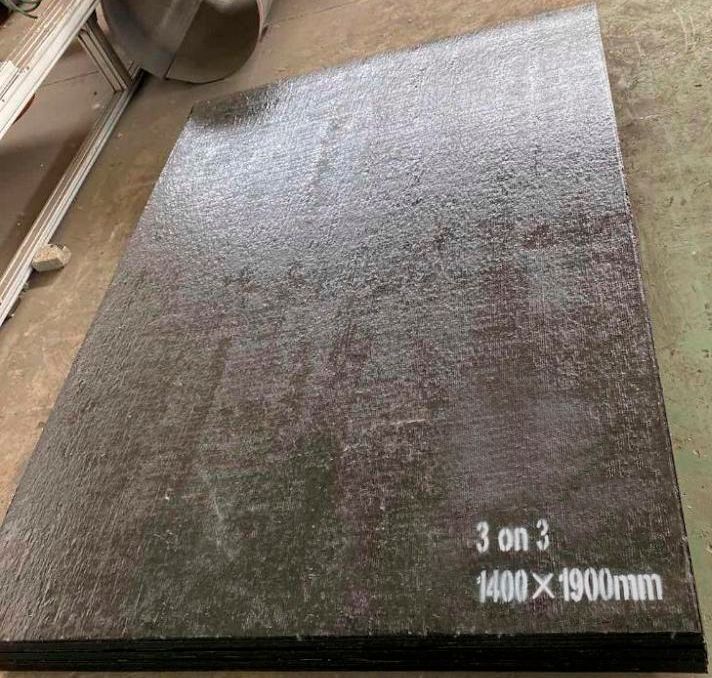

Download PDFBimetal hardfacing wear plates are manufactured by bonding two different types of metals together, typically a low carbon steel base layer and a high carbon or high chromium alloy layer.

The low carbon steel base layer provides structural support and toughness, while the high carbon or high chromium alloy layer provides excellent wear resistance and hardness. The combination of these two metals creates a wear-resistant surface that can withstand high levels of abrasion, impact, and heat.

The bimetal hardfacing wear plates can be easily fabricated and shaped to fit different equipment surfaces, including chutes, hoppers, excavator buckets, and conveyor systems. They are commonly used in industries such as mining, cement, steel, power generation, and recycling.

1. Extended equipment life: These plates significantly increase the lifespan and durability of machinery, reducing maintenance and downtime costs.

2. Superior wear resistance: The high carbon or high chromium alloy layer provides excellent resistance against abrasion, erosion, and impact.

3. Easy installation and replacement: The plates can be easily welded or bolted onto equipment surfaces, and damaged plates can be quickly replaced.

4. Versatility: Bimetal hardfacing wear plates can be customized to fit different shapes and sizes, making them suitable for a wide range of applications.

5. Cost-effective: The extended lifespan of equipment and reduced maintenance requirements translate into cost savings for businesses.

Overall, bimetal hardfacing wear plates are a reliable and effective solution for protecting equipment and machinery in high-wear environments, ensuring optimal performance and longevity.

Bimetallic wear plates are chosen for their unique advantages in various industrial applications.

The combination of different materials in these plates provides enhanced wear resistance and durability.

Placas bimetalicas al alto cromo (Cr)

Placas bimetalicas al cromo niobio (CrNb)

Placas bimetalicas al cromo niobio, vanadio, tungsteno (CrNbVW)

Placas ultraligeras tipo CCMAX de alta dureza y resistencia a abrasión/erosión

Bimetallic wear plate is an overlay weld resistant to the formation of a wear-resistant layer based on Cr7C3 carbide with a volume fraction of 50% or more on a common steel plate (Q235(A3) or heat-resistant steel (15CrMo, 12Cr1MoV, etc.) or stainless steel plate.

Bimetallic wear plate has high wear resistance, impact resistance, deformable and weldable performance characteristics, like steel plates can be directly rolled plate deformation, cutting and punching and other processes, processing into wear-resistant parts.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.