Nitronic 30 is a type of austenitic stainless steel, also known as UNS S20400.

Nitronic 30 is a nitrogen-strengthened austenitic stainless steel developed for applications requiring good aqueous corrosion resistance combined with good resistance to abrasive and metal-to-metal wear.

Coal handling equipment: screens, chute liners, buckets. Well screens, mixing tanks, hose clamps. Mining equipment

NITRONIC 30 Stainless Steel offers significantly higher strength than Type 304 and potential for applications requiring good resistance to aqueous and atmospheric corrosion resistance combined with good toughness and economy.

Specific potential applications include automotive hose clamps, safety belt anchors, truck and bus frames, water supply and control structures, sewage treatment plant structures, bulk solids handling equipment, magnetic ore separator screens, coal buckets and hopper cars.

components in the transportation industry. Bus space frames and bumpers take advantage of the excellent fabricability and high strength and toughness of stainless. Tensilized NITRONIC 30 Stainless Steel has been used in rapid transit structurals where the strength-to-weight ratio of up to three times that of carbon steel has improved operating efficiency. Rear frames of refrigerated trucks are easily welded and formed from NITRONIC 30 Stainless Steel, resulting in protective units that can withstand impact blows without cracking. Shipboard container structurals use stainless steel successfully because carbon steel becomes scuffed and rusts wherever the paint is damaged.

10% Cold Work

Ultimate Tensile Strength: 124 KSI (856 MPa)

Yield Strength: 78 KSI (539 MPa)

Elongation: 44%

Hardness: Re 23.5

20% Cold Work

Ultimate Tensile Strength: 150 KSI (1038 MPa)

Yield Strength: 101 KSI (696 MPa)

Elongation: 29%

Hardness: Re 34.5

30% Cold Work

Ultimate Tensile Strength: 174 KSI (1204 MPa)

Yield Strength: 137 KSI (948 MPa)

Elongation: 20%

Hardness: Re 39

40% Cold Work

Ultimate Tensile Strength: 204 KSI (1411 MPa)

Yield Strength: 173 KSI (1195 MPa)

Elongation: 8%

Hardness: Re 44

50% Cold Work

Ultimate Tensile Strength: 204 KSI (1411 MPa)

Yield Strength: 173 KSI (1195 MPa)

Elongation: 8%

Hardness: Re 44

60% Cold Work

Ultimate Tensile Strength: 214 KSI (1478 MPa)

Yield Strength: 184 KSI (1271 MPa)

Elongation: 6%

Hardness: Re 45

NITRONIC 30 has high impact resistance, making it ideal for a range of heavy duty applications. The NITRONIC30 has proven to be the endurance leader in coal handling equipment and coal preparation plants, with a lifespan twice that of its nearest competitor.

Choosing the best material for the job goes well beyond the initial price of the material. Maintenance, downtime and replacement costs associated with poor material performance can wreak havoc on production time and budgets. NITRONIC30 has been designed with these realities in mind.

NITRONIC®30 is an excellent grade to replace AR400, it is a wear-resistant steel, wear-resistant and corrosion-resistant, wear-resistant stainless steel. Fabrication, including bending and welding, is permitted. Mainly used for abrasion resistance to coal, gravel and other substrates. Truck chassis and bucket liners as well as chutes and gates are the main applications.

Annealing

Nitronic 30™ is soaked at 1038-1121°C (1900-2050°F) followed by rapid quenching in water or air.

Welding

Nitronic 30™ is a nitrogen strengthened and austenitic steel possessing high strength and corrosion resistance. This alloy can be readily welded and is non-magnetic even after rough forming operations.

Forging

Nitronic 30™ is heated to 1093°C (2000°F), soaked and again heated to 1176°C (2150°F) and finally equalized before being forged.

Forming

In the forming process Nitronic 30™ need not be per-heated. Commonly used welding techniques can be used to form this alloy.

Machinability

Commonly used machining techniques can be used for Nitronic 30™. Good machining results can be obtained based on the utilization of resulfurized lubricant and positive and slow speeds. Breakers and curlers are used in the welding process due to the thready and tough texture of the chips.

Hardening

Nitronic 30™ can be hardened through a cold working process and hardening will not take place when this alloy is exposed to thermal treatment.

Nitronic 30 (UNS S20400) is an austenitic stainless steel that has been strengthened with nitrogen, making it suitable for various applications that demand excellent resistance to corrosion in aqueous environments, as well as toughness and cost-effectiveness. Compared to type 304, Nitronic 30 exhibits considerably higher strength, enabling the use of thinner gauges to achieve additional cost savings. Moreover, Nitronic 30 demonstrates rapid work hardening while maintaining its ductility, and it can be easily welded and formed.

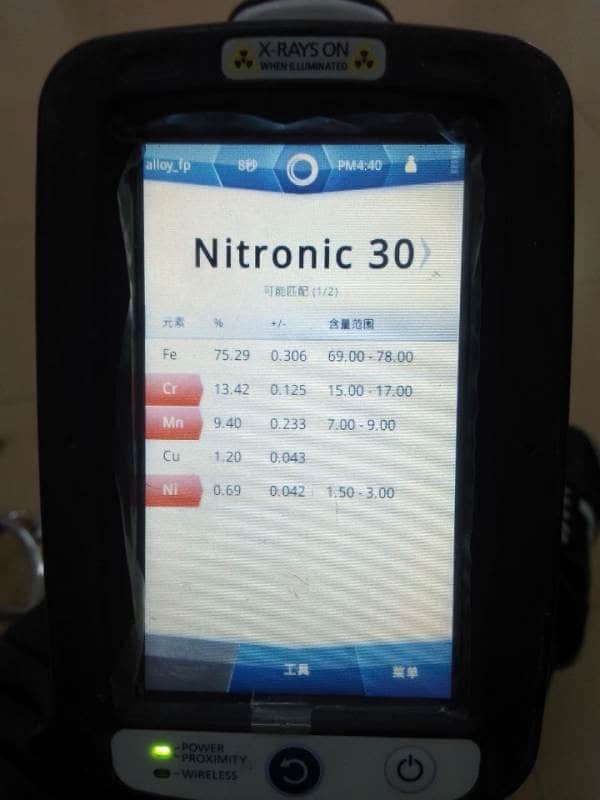

| Material | Cr | P | S | Ni | Si | C | Mn | Cu |

|---|---|---|---|---|---|---|---|---|

| Nitronic 30 | 15.0-17.0 | 0.04max | 0.03max | 1.50-3.00 | 1.00max | 0.03max | 7.00-9.00 | 1.00max |

| Material | Tensile strength | Yield strength 0.2% | Elongation | Hardness HB30 |

|---|---|---|---|---|

| Nitronic 30 | 758N/mm² | 379N/mm² | 50% | 95HB |

Nitronic 30 demonstrates favorable corrosion resistance across a range of environments. When compared to type 304, its pitting resistance surpasses that of type 304, as evidenced by tests conducted in a 10% FeCl3 solution. In sulfuric acid and hydrochloric acid, Nitronic 30 outperforms types 409 and 410 and approaches the corrosion resistance of type 304, particularly in more diluted solutions. However, it is important to exercise caution when dealing with reducing acids. If activated, Nitronic 30 may not readily repassivate when exposed to HCI or H2SO4, potentially leading to significant corrosion.

Nitronic 30 stainless steel cannot be hardened by using heat treatment. Heat treatment is often employed on Nitronic 30 to alleviate residual stresses that may have arisen during fabrication or machining. The specific heating process and temperature range depend on the desired stress relief and the application's specific requirements. Typically, the material is heated within the range of 500-600°C (932-1112°F) and held at that temperature for an appropriate duration to facilitate stress relaxation. Following the heating process, controlled cooling is implemented to prevent the formation of new stresses. Pickling is a widely used technique for eliminating surface impurities and oxide layers from Nitronic 30. It involves immersing the material in a pickling solution, typically comprising acids, to dissolve contaminants and restore the material's corrosion resistance. During the pickling process, it is crucial to carefully regulate the concentration and temperature of the pickling solution to avoid excessive etching or corrosion of the stainless steel surface.

Nitronic 30 is highly regarded for its exceptional formability, both in hot and cold working conditions. It can be easily shaped into a variety of sizes and configurations using standard forming techniques.

Within the temperature range of 1175-1200°C (2147-2192°F), Nitronic 30 stainless steel becomes more malleable and can be efficiently shaped through processes such as hot rolling, hot forging, and hot extrusion. Hot forming is commonly employed for larger and more intricate components that necessitate substantial deformation or shaping.

Nitronic 30 also demonstrates excellent cold formability, allowing for shaping and deformation at room temperature through techniques like cold rolling, cold drawing, bending, and stamping. Cold forming is often utilized to produce smaller components, intricate shapes, and parts with strict dimensional tolerances. It is worth noting that Nitronic 30 stainless steel may work-harden during cold forming, requiring intermittent annealing to restore its ductility and prevent cracking.

While Nitronic 30 shares similar machinability characteristics with other austenitic stainless steels, its high work hardening rate necessitates the use of robust machinery equipped with carbide-coated tools during the machining process. Additionally, the material requires more rigid clamping and lower cutting speeds to achieve optimal results.

Nitronic 30 stainless steel is typically regarded as weldable using common fusion and resistance welding techniques, including high-frequency tube and pipe welding. Its weldability is comparable to that of type 304L, with one notable difference being that Nitronic 30 requires a slower arc welding speed to achieve proper penetration. When a weld filler is required, AWS E/ER 308L, 309L, and 209 are commonly recommended. It is crucial to ensure the formation of ferrite in the weld deposit to prevent the occurrence of weld "hot cracking."

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.