GB Q235 Steel Channel is a type of carbon structural steel that is commonly used in construction and machinery.

It is known for its good plasticity, weldability, and moderate carbon content.

Q235 is also referred to as Q235A, Q235B, Q235C, and Q235D, with each designation indicating different variations of the steel. It is widely used in the engineering and construction industries.

Q235 steel is a plain carbon structural steel that is widely used in China. Here are some key properties and characteristics of Q235 steel:

- Q235 is a mild steel and does not require heat treatment for production.

- The "Q" in Q235 designates the yield point, while the "235" indicates the yield strength.

- Q235 has good plasticity and weldability.

- As the thickness of the material increases, the yield value of Q235 decreases.

- Q235 has comprehensive and adequate performance due to its moderate carbon content.

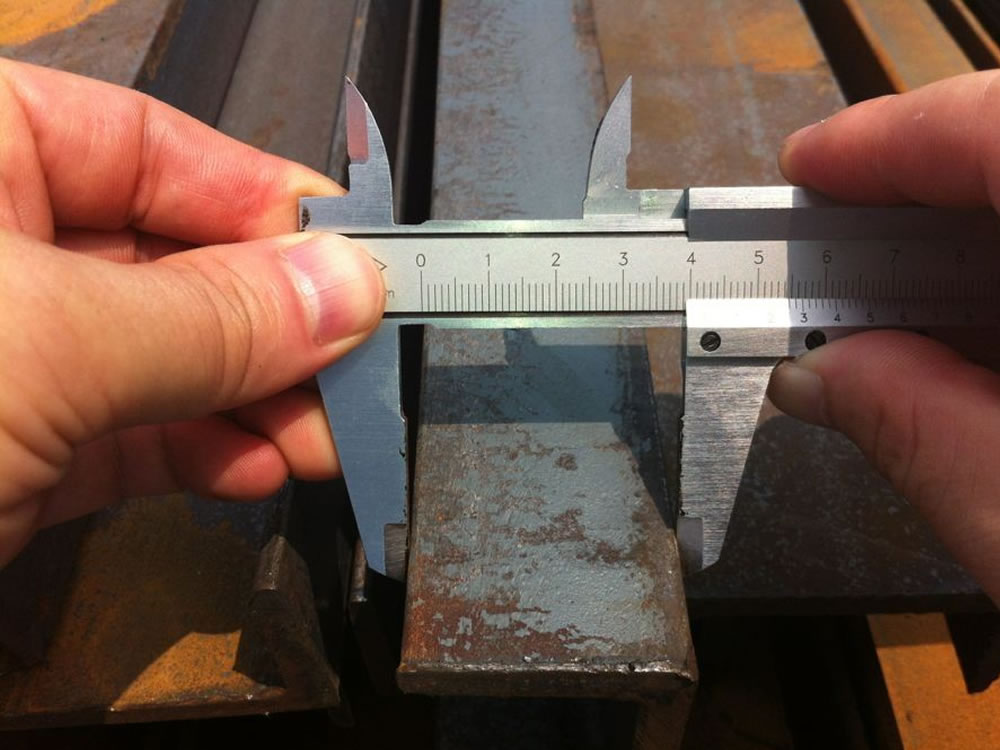

- It is commonly rolled into steel plates, rods, bars, or angle frames.

Q235 steel can be substituted with equivalent materials that include:

- A36 (USA ASTM)

- Q235 (China GB/T)

- SS400 (Vietnam/Japanese JIS)

Q235 steel channel is widely used in the engineering and construction industries. It is commonly used for the following applications:

- Construction of buildings and structures

- Machinery and equipment manufacturing

- Support structures for bridges and highways

- Frameworks for vehicles and ships

- Manufacturing of various metal components.

GB Q235 Steel Channel is a carbon structural steel widely used in construction and machinery. It has good plasticity, weldability, and moderate carbon content. Q235 is commonly rolled into steel plates, rods, bars, or angle frames and is widely used in the engineering and construction industries. It can be substituted with equivalent materials such as A36 (USA ASTM) and SS400 (Vietnam/Japanese JIS).

| Size | Specification(mm) | Specification(mm) | Specification(mm) | Theory Weight (kg/m) |

|---|---|---|---|---|

| h | b | d | ||

| 5# | 50 | 37 | 4.5 | 5.438 |

| 6.3# | 63 | 40 | 4.8 | 6.634 |

| 8# | 80 | 43 | 5 | 8.045 |

| 10# | 100 | 48 | 5.3 | 10.007 |

| 12# | 120 | 53 | 5.5 | 12.059 |

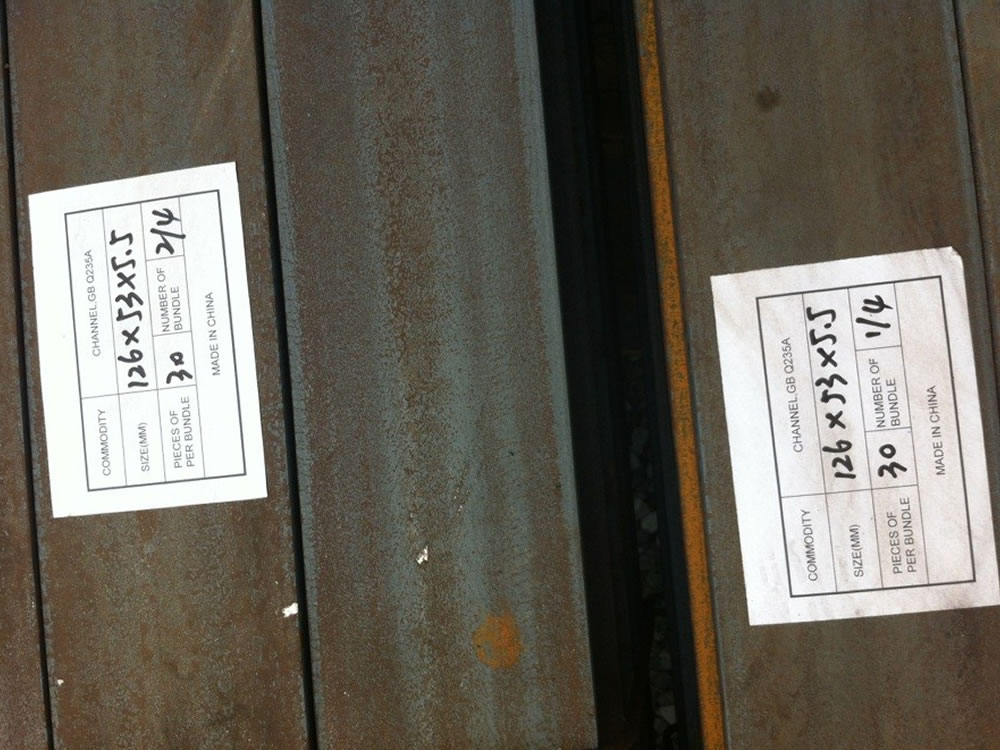

| 12.6 | 126 | 53 | 5.5 | 12.319 |

| 14#a | 140 | 58 | 6 | 14.535 |

| 14#b | 140 | 60 | 8 | 16.733 |

| 16#a | 160 | 63 | 6.5 | 17.24 |

| 16#b | 160 | 65 | 8.5 | 19.752 |

| 18#a | 180 | 68 | 7 | 20.174 |

| 18#b | 180 | 70 | 9 | 23 |

| 20#a | 200 | 73 | 7 | 22.637 |

| 20#b | 200 | 75 | 9 | 25.777 |

| 22#a | 220 | 77 | 7 | 24.999 |

| 22#b | 220 | 79 | 9 | 28.453 |

| 25#a | 250 | 78 | 7 | 27.41 |

| 25#b | 250 | 80 | 9 | 31.335 |

| 28#a | 280 | 82 | 7.5 | 31.427 |

| 28#b | 280 | 84 | 9.5 | 35.832 |

| 30#a | 300 | 85 | 7.5 | 34.463 |

| 30#b | 300 | 87 | 9.5 | 39.173 |

| 32#a | 320 | 88 | 8 | 38.083 |

| 32#b | 320 | 90 | 10 | 43.107 |

| 36#a | 360 | 96 | 9 | 47.814 |

| 36#b | 360 | 98 | 11 | 53.466 |

| 40#a | 400 | 100 | 10 | 58.928 |

| 40#b | 400 | 102 | 12.5 | 65.208 |

The MS Channel is suitable for construction projects involving warehouses, workshops, sports stadiums and car parks, among others.Hot rolled channel steel is categorised as carbon structural steel, a material of choice in the construction and machinery industries.Specifically, hot rolled channel steel is employed in the construction of architectural structures, where it can be welded to support or suspend various facilities. It is often used in combination with I-beams. The hot rolled channel steel we supply must possess perfect welding, riveting and mechanical properties.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.